Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Gold-Iridium Catalyst Particles Remain Stable On Titania Support

Catalysis: Study reveals source of alloy nanoparticles’ knack for resisting sintering

by Mitch Jacoby

November 16, 2015

| A version of this story appeared in

Volume 93, Issue 45

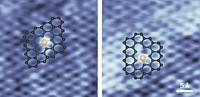

Metal nanoparticles supported on solids are widely used as catalysts to drive petroleum refining, automobile emissions cleanup, and other processes. But prolonged exposure to high temperature causes these particles to wander across the support and coalesce, or sinter, with other catalyst particles. That process buries the particles’ active sites, causing the catalyst to become ineffective. Gold nanoparticles are especially prone to this form of deactivation and therefore the metal is not typically used, despite its exceptional activity at low temperature. Thanks to a study led by Volkan Ortalan and Jeffrey Greeley of Purdue University, researchers may want to reconsider gold’s catalytic potential. The team found that alloying gold with a small amount of iridium via sequential deposition of the metals on TiO2 produced gold-iridium nanoparticles that strongly resist sintering even at 500 °C (Nano Lett. 2015, DOI: 10.1021/acs.nanolett.5b03585). An analysis involving electron tomography and quantum calculations revealed that iridium preferentially collects at the interface between the particles and TiO2. That arrangement increases the particles’ adhesion to TiO2 and reduces the thermodynamic driving force to sinter relative to pure gold nanoparticles.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter