Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Quick Chemical Trick Makes Surfaces Slick

Surface Chemistry: After a dip in a silane-isopropanol-acid brew, surfaces get a liquid coating that makes other liquids slide off

by Bethany Halford

November 23, 2015

| A version of this story appeared in

Volume 93, Issue 46

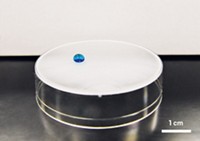

A quick dip in a special silane solution followed by a few moments of drying is all it takes to give a surface an omniphobic coating that repels both water and organic liquids. Such superslippery coatings could find use on windshields and airplane wings (Angew. Chem. Int. Ed. 2015, DOI: 10.1002/anie.201509385). Previous examples of omniphobic surfaces have relied on either constructed nanoscale features or a thin layer of liquid to make other liquids slide off. But under enough pressure liquids can penetrate a nanostructured surface so that they’re no longer repelled, and in the case of surfaces that have a liquid layer, the liquid can be depleted. Liming Wang and Thomas J. McCarthy of the University of Massachusetts, Amherst, have come up with a different approach: They covalently attach a layer of liquid onto a substrate. When other liquids such as water and toluene encounter the surface, they slide right off. Making the omniphobic coating is easy and fast, McCarthy tells C&EN. One simply dips the substrate into an isopropanol solution of dimethyldimethoxysilane and sulfuric acid. After a few minutes of drying, the coating is ready to repel liquids.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter