Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Wet Method Grows Ultrathin Films

Catalysis: Electrochemical technique provides atom-efficient route to making iridium catalysts

by Mitch Jacoby

November 30, 2015

| A version of this story appeared in

Volume 93, Issue 47

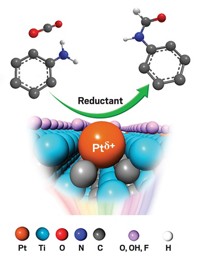

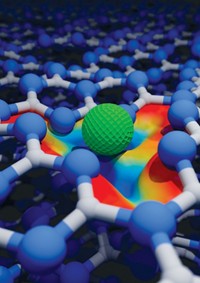

Researchers at the National Institute of Standards & Technology have developed a wet-phase analog of atomic layer deposition (ALD), a gas-phase thin-film growth method, and used it to prepare highly active iridium catalysts for water splitting (Energy Environ. Sci. 2015, DOI: 10.1039/c5ee02541a). ALD is touted for its ability to grow a predetermined number of atomic layers of a material only where the film is wanted, but the method requires costly, dedicated equipment. So NIST staff scientist Thomas P. Moffat and coworkers developed an inexpensive solution phase alternative. The team showed that its electrochemical layer-by-layer technique can be used to grow ultrathin films of iridium, a rare and expensive catalytic metal, by using an electrolyte solution containing K3IrCl6, Na2SO4, and H2SO4. The scientists grew films of iridium on gold, platinum, and nickel and evaluated them as catalysts for water splitting, a process that generates valuable hydrogen fuel. The team reports that the catalytic activity of its iridium films, just one monolayer thick, matches the top performing bulk polycrystalline iridium electrodes, demonstrating that the new deposition method provides a simple way to use this precious metal efficiently.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter