Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Gauging The Carbon Cost Of Fuel From Canadian Oil Sands

Environment: New study finds that greenhouse gas emissions associated with fuel from Alberta oil sands are about 20% greater than those for U.S. crude oil

by Deirdre Lockwood

June 22, 2015

The oil sands of Canada’s Alberta province are one of the world’s largest oil reserves, currently producing the equivalent of 2 million barrels of crude oil per day. But it takes lots of energy to transform the heavy bitumen in the deposits, which is bound up with sand and clay, into diesel and gasoline. A new study presents a comprehensive analysis of the greenhouse gas emissions associated with fuels from the oil sands—from extracting to shipping to refining to burning—and concludes that emissions are about 20% greater than those from fuels produced from conventionally extracted crude oil in the U.S. (Environ. Sci. Technol. 2015, DOI: 10.1021/acs.est.5b01255).

Currently, only about 9% of crude oil processed by refineries in the U.S. comes from the Canadian oil sands, but analysts project that this share will grow in the future, especially if long-distance pipeline projects such as Keystone XL go forward. Researchers want to understand the carbon footprint of these fuels to help assess their impact on climate, and to track progress toward emission reduction targets. So Hao Cai of Argonne National Laboratory and his colleagues set out to determine the greenhouse gas emissions associated with all the steps involved in production and use of oil sands products refined in the U.S., often called a “well to wheels” life-cycle assessment.

Previous assessments have suffered from limited, proprietary data or were based on less energy-efficient oil production processes than those used today. In the new study, the researchers used publicly available monthly operations data from 27 oil sands projects between 2008 and 2012 and assessed emissions using a model developed at Argonne. The operations data allow the model to estimate emissions resulting from powering the machinery needed to extract oil from the sands, heating steam used in the process, and even from bacteria giving off carbon dioxide and methane in wastewater ponds.

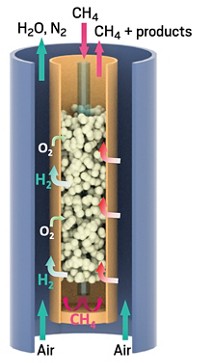

The journey from well to wheels begins with extraction. In surface mining, oil companies use trucks to dig up shallow sands, rinse them with hot water, and shake the mixture to separate out the bitumen. For deeper deposits, they drill wells and inject steam to separate the bitumen from the sands, and then pump it out—a method called in situ recovery. Once the heavy bitumen is recovered, it is diluted with lighter hydrocarbons so it can be more easily transported to a refinery or partially refined on-site into a mixture called synthetic crude.

With the model, the researchers considered four different production scenarios—using either surface mining or in situ recovery for production of either bitumen or synthetic crude oil. Each scenario included pipeline transportation to the U.S., refinement into gasoline or diesel, and combustion.

The team found that gasoline and diesel production from oil sands yielded, on average, about 20% greater emissions than fuel production from conventional crude oil, similar to previous estimates. The most intensive emissions came from in situ recovery of synthetic crude oil and the least intensive from surface mining of bitumen. The most common methods used in the industry, in situ recovery of bitumen and surface mining of synthetic crude, each had about 20% greater emissions compared with conventional crude production.

“This study takes a significant step forward in comprehensiveness and quality of its life-cycle emissions estimates,” says David W. Keith, an expert in climate science and energy policy at Harvard University. This is a politically hot topic, he suggests, and the study “helps to provide an evenhanded look.”.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter