Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Hydrogen Power

Method converts petroleum to hydrogen and produces little CO2

Advance relies on using microwaves to directly heat iron catalyst

by Mitch Jacoby

November 16, 2018

| A version of this story appeared in

Volume 96, Issue 46

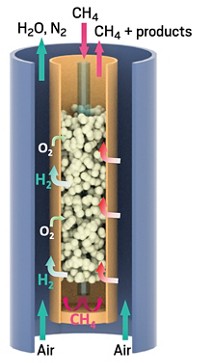

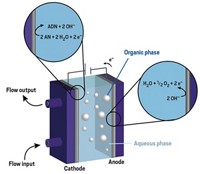

Petroleum is a relatively inexpensive, abundant, and convenient source of energy. One of the biggest drawbacks to using it as fuel is that doing so generates copious amounts of carbon dioxide, a greenhouse gas. Researchers in the U.K. and Saudi Arabia have taken a step toward mitigating that problem by demonstrating a CO2-free method for converting petroleum samples to high-purity hydrogen, a clean-burning fuel, and solid carbon, which can be stored underground safely or used commercially. Currently, most hydrogen comes from steam reforming methane, an energy-intensive process that produces a lot of CO2. Developed by Peter P. Edwards of the University of Oxford, John M. Thomas of the University of Cambridge, and coworkers, the new method uses microwaves to directly energize a low-cost iron nanoparticle catalyst, as opposed to using conventional heating, in which the heated fuel activates the catalyst (Energy Environ. Sci. 2018, DOI: 10.1039/c8ee02444h). Tests on diesel, gasoline, and methane show that the microwaves immediately generate gas, more than 90% of which is hydrogen. For heavy crude samples, the purity is roughly 80%. In contrast, the same catalyst, heated conventionally, converted diesel to 65% hydrogen and a mixture of alkanes, alkenes, and other gases.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter