Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

New route to lead-free porcelain designs discovered

Method inspired by traditional Japanese akae enameling

by Jyllian Kemsley

May 9, 2016

| A version of this story appeared in

Volume 94, Issue 19

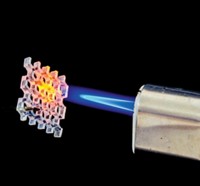

Akae is a traditional Japanese enameling technique used to decorate porcelain. Historically, it involved combining leaded glass powder with iron(III) oxide in a water-based solution to yield a red paint. As porcelain makers have tried to switch to lead-free glass, however, they have had trouble producing high-quality akae samples. Experiments combining various particle sizes of glass and iron(III) oxide now seem to provide an optimal recipe that yields a glass particle core coated with an iron(III) oxide shell, reports a team led by Hideki Hashimoto of Kogakuin University. In contrast, the researchers find that preparing akae paint such that the iron oxide is isolated in spaces between glass particles results in a lower quality enamel (ACS Appl. Mater. Interfaces 2016, DOI: 10.1021/acsami.6b01549). The group succeeded in preparing the core-shell material by combining 2-µm glass particles with 100-nm iron(III) oxide particles, but the details of the preparation method were key: They blended the particles with green tea solution in a mortar and let the mixture dry, repeating the process a total of three times. Because mortars and pestles are commonly used by porcelain artisans, the authors believe that the method should be easy to implement.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter