Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

How silver ink and lasers can create twisted 3-D components

A new printing method could help create custom wiring for miniature electronics

by Matt Davenport

May 23, 2016

| A version of this story appeared in

Volume 94, Issue 21

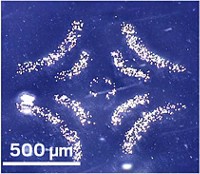

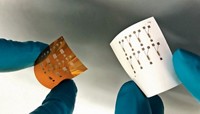

When Mark A. Skylar-Scott says he and his Harvard University colleagues can make metal filaments in midair, he stresses that they aren’t defying gravity. The team’s silver strands start attached to a substrate, but the researchers can draw them out through three-dimensional space to create intricate patterns. Led by Skylar-Scott and Jennifer A. Lewis, the researchers are forging the 3-D silver wires on demand using a nanoparticle ink and laser light (Proc. Natl. Acad. Sci. USA 2016, DOI: 10.1073/pnas.1525131113). The approach could help create custom transmitters and electrical connections for biosensors and other miniaturized devices, the researchers say. The ink consists of silver nanoparticles mixed with polyacrylic acid. The polymer chains prevent the silver particles from clumping while also serving as a binder to give the ink the consistency of toothpaste, Skylar-Scott says. A computer-controlled nozzle moves in 3-D to squeeze the ink into the focal point of an infrared laser, which moves in concert with the nozzle. The laser’s heat vaporizes the polymer and sinters the nanoparticles into a solid metal wire. This laser-assisted method enables the team to directly write wire patterns onto low-cost substrates that can’t support conventional high-temperature annealing.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter