Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

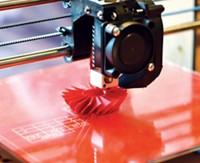

Buyer Beware Of 3-D Printer Emissions

Indoor Air Pollution: Particulates and volatile organic compounds could reach harmful levels in office-sized spaces

by Jyllian Kemsley

January 25, 2016

| A version of this story appeared in

Volume 94, Issue 4

As costs of three-dimensional printers drop and the devices increasingly make their way into offices, schools, and homes, users should consider how to limit exposure to emissions of particles and gases in the space where the printer is located. This caution stems from research by a team led by Brent Stephens of Illinois Institute of Technology and Neil E. Crain of the University of Texas, Austin (Environ. Sci. Technol. 2016, DOI: 10.1021/acs.est.5b04983). The researchers tested the emissions of five commercially available desktop 3-D polymer-extrusion printers for ultrafine particles, which have a diameter less than 100 nm, and volatile organic compounds, including caprolactam and styrene. They used the printers to make a standard part from nine different polymer filament starting materials. The emissions varied more by the type of material than they did by the type of printer. Modeling the emissions in a 45 m3 air-conditioned office, the team predicts that caprolactam and styrene would reach concentrations that could be harmful to health.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter