Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Samsung: Flaws led to Note 7 fires

Independent auditors fault suppliers for defective batteries

by Alexander H. Tullo

January 24, 2017

| A version of this story appeared in

Volume 95, Issue 5

Samsung’s investigation into the batteries of its Galaxy Note 7 phones has uncovered several manufacturing defects that likely contributed to the rash of phone fires customers experienced after the phone’s launch last year.

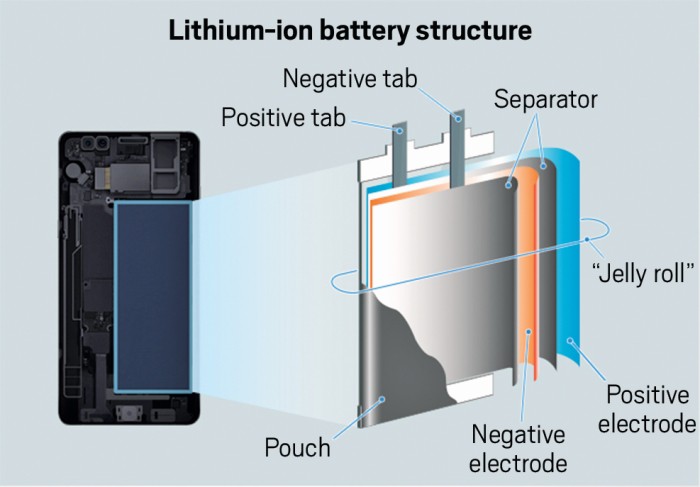

Billions of batteries are used every day without incident, but when batteries do catch fire, common causes include a short circuit across the battery separator, a porous polyethylene film which is supposed to prevent battery electrodes from touching. Batteries can also overcharge or experience a chemical breakdown of their flammable carbonate-based electrolytes.

At a press conference on Monday at its Seoul headquarters, Samsung disclosed results of analysis by two independent investigators: the testing firm Underwriters Laboratories (UL) and the engineering consulting firm Exponent. The firms tested batteries made by two batteries suppliers, dubbed in their presentations as “Company A” and Company B”. The suppliers are believed to be Samsung SDI and Amperex Technology.

UL performed a teardown analysis on damaged Note 7 phones and did a failure analysis on hundreds of pristine batteries. In a presentation, Sajeev Jesudas, president of UL’s consumer business unit, said the damaged Company A batteries showed signs of internal short circuits. In many of the undamaged batteries, UL noticed deformation in the upper right corners. The company says a likely failure mechanism is that the deformation, plus the mechanical stress of charging and discharging, probably damaged the separator, short-circuiting the battery.

For Company B, UL found missing insulation tape in some battery electrodes and welded spots that protruded into the battery structure.

Elaborating further, Kevin White, principal scientist at Exponent, suggested the damage to the Company A battery corners may have been caused by a pouch design that didn’t accommodate the volume of the electrode assembly, leading to short circuits across the separator. He also pointed to the sharp welds as a possible culprit in the Company B batteries.

Samsung says it is implementing new quality-control procedures for its batteries, including an eight-point safety check and has retained outside advisers to consult on battery design and safety.

K. M. Abraham, principal of the battery consulting firm E-KEM Sciences and a professor at Northeastern University, says that battery companies have been making the separator—critical to battery safety—thinner and thinner in order to increase the amount of electrode materials in the battery, thereby increasing energy storage capacity. “A thinner separator, together with a manufacturing flaw, is a calamity waiting to happen,” he says.

New separator chemistry, he adds, may make batteries safer. “Companies are moving to mechanically stronger and higher-temperature-performance separators made out of composites of polyethylene or other polymers and ceramics,” Abraham says. It is unlikely, he adds, that Samsung used these in the Note 7.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter