Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Engineered Tissue On A String

Cell-filled fibers can be woven into three-dimensional structures for therapeutic applications

by Celia Henry Arnaud

April 8, 2013

| A version of this story appeared in

Volume 91, Issue 14

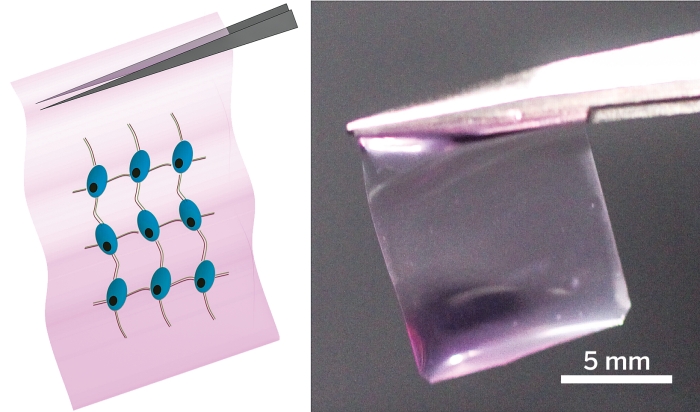

Long, thin fibrous materials would be attractive for tissue engineering if there were a good way to incorporate cells and extracellular matrix proteins into the fibers. Shoji Takeuchi and coworkers at the University of Tokyo have now made that wish come true (Nat. Mater., DOI: 10.1038/nmat3606). The researchers took advantage of double-coaxial laminar flow in a microfluidic device to fabricate fibers with a tough calcium alginate shell around cells and extracellular matrix proteins such as collagen or fibrinogen. The calcium alginate quickly forms a stable hydrogel that holds the proteins in place so they can also gel. After the researchers culture cells in the core, they remove the outer shell by enzymatic digestion. They made meter-long fibers with a variety of cell types, including structural, muscle, epithelial, and nerve cells. The cell-containing fibers function just like their constituent cells. The researchers made three-dimensional structures by braiding and weaving the yarnlike fibers. In a test of the materials, they implanted 20-cm-long, insulin-secreting pancreatic cell fibers into diabetic mice. The fibers normalized blood glucose levels in the mice for almost two weeks.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter