Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy Storage

Screen-printed, flexible battery could be low-cost power source for wearable electronics

New Ag-Zn battery is more powerful than Li-ion versions and could be made on a large-scale

by Prachi Patel, special to C&EN

December 14, 2020

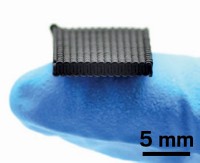

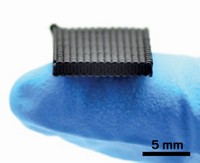

Researchers have developed a way to make high-power, flexible, and stretchable batteries by the dozens using a screen-printing technique much like that used for printing T-shirts (Joule 2020, DOI: 10.1016/j.joule.2020.11.008). The method lets them make silver–zinc batteries, which are based on a decades-old chemistry, in any shape and size, and it paves the way for manufacturing rolls of the batteries quickly at low cost.

The new, stretchy, twistable battery can provide at least five times as much power as lithium-ion cells of the same area—enough for two 4 cm2 batteries to power a palm-sized flexible display. Its high charge capacity and pliability make the battery ideal for powering wearable gadgets and small, lightweight sensors and wireless networking devices, says its developer Shirley Meng, a materials scientist at the University of California San Diego.

Researchers have tried many ways to make flexible batteries, often out of polymers, that complement wearable gadgets of the future. But methods like 3-D printing used to make such polymer-based batteries are complex, costly, and slow, Meng says. There is a need for a way to make tens of millions of high-performance, flexible batteries at low cost.

Looking to meet this need, Meng, UCSD nanoengineer Joseph Wang, and their colleagues wondered whether screen-printing could be a low-cost method to build batteries at scale. They picked silver oxide–zinc batteries, first developed by NASA in the 1960s and used in hearing aids because of their high energy density and safe chemistry. The team collaborated with the company ZPower, which is commercializing a new, rechargeable version of these batteries.

The UCSD team started with the company’s proprietary AgO cathode material for their printable batteries. Wang’s team used polymer binders and easily available solvents to make ink versions of all the battery parts, including electrodes, a potassium hydroxide–poly(vinyl alcohol) hydrogel electrolyte, and other components. Printing each layer involved squeezing the inks with a metal-blade squeegee through stainless steel stencils onto thin, transparent rubbery films and then curing them in an oven for a few minutes. They built a cathode with layers of different inks on one film and built an anode similarly on another. They sandwiched a printed electrolyte layer between the electrodes to build batteries less than 1 mm thick.

The battery has is the highest charge capacity by area of any flexible battery reported so far, Meng says. And it could easily be printed on a large scale using a roll-to-roll process. The researchers made batteries of varying dimensions and were able to power a flexible black-and-white electronic display using two 4 cm2 batteries. The team is now working to improve the device’s cycle life: it can only be recharged about 80 times before the charge-holding capacity starts fading.

The screen-printing process reported here is a key advance that allows the researchers to make batteries of various sizes and thicknesses that can be specifically customized to electronic devices, says Sang-Young Lee, a chemical engineer at the Ulsan National Institute of Science and Technology. The high charge capacity and low cost are also an important advantage over other zinc and lithium-ion batteries, he says. Boosting cycle life is now the key hurdle to clear for making these batteries practical, he concludes.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter