Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Solar Power

Perovskite progress pushes tandem solar cells closer to market

Rapid improvements in the stability and efficiency of perovskite-silicon tandem cells are raising commercial hopes

by Mark Peplow, special to C&EN

June 11, 2018

| A version of this story appeared in

Volume 96, Issue 24

“It’s been quite incredible—I didn’t think it’d happen that quickly,” laughs Henry J. Snaith while reflecting on the remarkable rise of perovskite solar cells. From humble beginnings in 2009, when they converted sunlight into electricity with an efficiency of 3.8% and lasted only minutes, the best perovskite cells now boast an efficiency of 22.7% and routinely work for thousands of hours under harsh test conditions.

Snaith, a University of Oxford physicist, cofounded the spin-off Oxford PV in 2010 to commercialize perovskite cells, which use micrometer-thin films of cheap and easily processed materials to harness sunlight’s energy. Over the past few years, the company has focused on making “tandem cells,” devices that combine perovskites with silicon, the material currently dominating the photovoltaic world, to deliver more power than either could manage alone. Tandem devices not only promise cheaper solar electricity but also provide a route for perovskites to reach the market faster by piggybacking on the billion-dollar silicon solar industry.

This week, Oxford PV will announce its latest milestone: a perovskite-silicon tandem cell that offers an efficiency of 25.2%, a record for this type of device with a two-electrode architecture. Certified by the Fraunhofer Institute for Solar Energy Systems, the result comes from a 1-cm2 test cell. But the 243-cm2modules rolling off the company’s demonstration line in Brandenburg, Germany, are not far behind and have achieved more than 24% efficiency.

Because the best commercial silicon cells offer about 22% efficiency, these tandem cells are on the cusp of offering enough extra output to enter the market. Oxford PV plans to sell its technology to existing solar panel manufacturers rather than go into production itself and estimates that its perovskite coating should initially cost 22 cents per cell, including materials and manufacturing expenses. Potential customers are starting to visit the Brandenburg facility to see whether perovskites can indeed give their silicon cells a boost.

Oxford PV’s cells are a testament to two crucial areas of progress in perovskite research over the past few years: the materials’ longevity and their partnerships with silicon.

Until recently, perovskites were deemed far too unstable for an industry that expects solar modules to sustain their performance for 25 years or more. “They were so unstable five years ago, but there’s been a huge amount of progress,” says Stanford University’s Michael D. McGehee, who works on perovskite tandem cells. “It’s been pretty amazing.”

These stability improvements have also helped underpin the rapid progress of tandem cells. And Oxford PV’s devices are no fluke: Several other research groups are on the verge of publishing details about perovskite-silicon tandems that top 25% efficiency, a sign of how reliable the technology has become. “Finally, things are falling into place,” says Michael Grätzel at the Swiss Federal Institute of Technology, Lausanne (EPFL), one of the pioneers of perovskite research.

In the lab, perovskite solar cells have improved their efficiencies at an unprecedented rate over the past few years, whereas single-crystal silicon cells have seen only marginal gains. Putting these materials together to make tandem cells offers a promising way to squeeze more power out of solar panels, a tactic that has made dramatic progress over the past three years.

Sources: Single-crystal silicon and stand-alone perovskite data adapted from NREL; tandem cell data from Adv. Mater. Interfaces 2017, DOI: 10.1002/admi.201700731; new data for two-terminal cell from Oxford PV

Tough enough?

The most widely used light-absorbing material in the first wave of stand-alone perovskite cells was methylammonium lead iodide. But the black cubic crystals that made this perovskite such a good photovoltaic material were extremely sensitive to air and moisture, rapidly morphing into a yellow orthorhombic form that rendered the cells useless.

To avoid this degradation, researchers have fine-tuned perovskites’ chemistry, making them much less sensitive to wear and tear—and better solar harvesters to boot. Last year, for example, Snaith showed that replacing methylammonium with the right blend of formamidinium, cesium, and butylammonium, and swapping some iodide for bromide, offered a better light absorber that was also more stable, making it an ideal partner for silicon (Nat. Energy 2017, DOI: 10.1038/nenergy.2017.135). “The mixed cations have come out as winners in both performance and stability,” Grätzel says.

Stability gains have come from altering other parts of the cells, too. Once light has freed negatively charged electrons and positively charged electron “holes” within a perovskite, substances sandwiching the perovskite extract these charges and shuttle them to an electrode to generate current. But a commonly used hole extractor material, spiro-OMeTAD, is doped with metal ions that can diffuse into the perovskite layer and weaken its crystal structure. Grätzel recently discovered that replacing spiro-OMeTAD with undoped copper(I) thiocyanate, protected by a scrim of reduced graphene oxide, rendered the cell vastly more stable while keeping efficiencies above 20% (Science 2017, DOI: 10.1126/science.aam5655). Conveniently, the thiocyanate salt is also about 1,000 times cheaper than spiro-OMeTAD, Grätzel says.

Working with more stable perovskites has helped scientists encapsulate the cells in protective coatings, further improving their longevity. McGehee, for example, has laminated perovskite cells with ethylene vinyl acetate, which dramatically improved the devices’ resistance to temperature swings (Energy Environ. Sci. 2018, DOI: 10.1039/c7ee02564e). That lamination process takes about 20 minutes at 140 °C, which would have killed the perovskite cells of two years ago, McGehee says.

Although Oxford PV is keeping the precise formulation of its 243-cm2 tandem cells under wraps, it has used many of these tactics to build devices that have passed longevity tests set by the International Electrotechnical Commission, which is essential for any commercial cell to be taken seriously.

The new cells can run for thousands of hours at 60 °C under one sun’s worth of artificial light, withstand temperature swings from –40 to 85 °C, and survive a stifling 85% relative humidity at 85 °C—all with less than 5% loss in performance. If the tandem cells behave similarly to silicon modules, these accelerated aging tests suggest that the cells are probably stable enough to deliver at least a decade of real-world use. Oxford PV now plans further tests, to offer more reassurance that their perovskites can match silicon’s longevity.

Some in the community urge caution when considering these seemingly impressive results, not least because perovskites have different degradation pathways than silicon. “We still have to understand these mechanisms better,” says Kylie Catchpole at Australian National University, who develops perovskite-silicon tandems. Grätzel adds that companies would likely want to see perovskites survive tests for 10,000 hours or more and worries that entering the market too early with products that fail after a few years could sour industry’s opinion of perovskites.

Snaith agrees there is still room for improvement: “In general, I don’t know if photovoltaic technologies could ever be too stable, and more effort on stability is always going to be useful. I’d like to make the materials as indestructible as possible.”

Oxford PV is also addressing long-standing concerns about perovskites’ lead content. The company’s cells contain about 0.3 g of the toxic element per square meter in a layer roughly 0.5 µm thick. Earlier this year, a life-cycle analysis of the firm’s tandem cells concluded that even if all that lead leeched out into the environment, it would contribute only 0.27% to the total potential freshwater ecotoxicity of the entire tandem cell. Overall, the silicon cell has a much worse environmental impact than perovskite, says Mariska de Wild-Scholten of the contract research firm SmartGreenScans, who carried out the analysis.

That’s because making a silicon panel requires vastly more energy and materials than a perovskite cell, de Wild-Scholten says. For instance, if silicon solar panels were deployed on a massive scale to generate 12.5 terawatts of power, those panels would consume three years’ worth of the world’s current silicon production, Snaith points out. In contrast, achieving that same 12.5 TW of power capacity with perovskites would take just a few days of lead production, meaning that it would not require a significant uptick in global lead consumption (Nat. Mater. 2018, DOI: 10.1038/s41563-018-0071-z).

A solar cell made for two

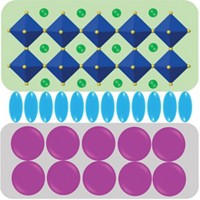

Uniting perovskites with silicon makes good commercial sense, says Chris Case, chief technology officer of Oxford PV, because existing photovoltaic manufacturers become potential customers rather than competitors. And it has proved relatively easy to tune perovskites so that they absorb the shorter, bluer wavelengths of the solar spectrum, allowing the remaining light to be collected by a silicon cell that prefers longer, redder rays. This strategy maximizes the amount of light absorbed by the overall tandem device.

The first perovskite-silicon tandem cell appeared in 2014, boasting a modest efficiency of 13.4% (Phys. Chem. Chem. Phys. 2014,DOI: 10.1039/c4cp03788j). It used the most basic tandem design, known as a four-terminal configuration. This geometry simply places a stand-alone perovskite cell with a transparent back on top of its silicon partner. In just three years, the efficiency of the best four-terminal devices skyrocketed to 26.4%. That champion tandem used a perovskite that was exceptionally transparent to longer wavelengths. “The key thing is not to kill the silicon cell when you put something on top of it,” says Catchpole, who led the work (Adv. Energy Mater.2017, DOI: 10.1002/aenm.201700228).

Advertisement

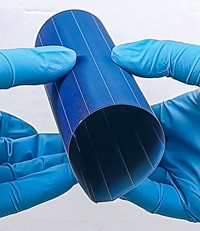

Oxford PV and other researchers have focused instead on a two-terminal architecture that coats perovskite directly onto a silicon cell, which they believe is more commercially viable. This design removes two electrodes from the device, lowering costs and directing more light to the silicon cell, though it is also trickier to make. The first of these devices debuted in 2015 with a 13.7% efficiency; Oxford PV’s announcement shows that figure has almost doubled in just three years.

Meanwhile, an EPFL team led by Christophe Ballif has also made a certified two-terminal tandem device that matches Oxford PV’s 25.2% and is described in a paper that, as of C&EN’s press time, had not yet been published. Jinsong Huang at the University of North Carolina, Chapel Hill, and coworkers have built a two-terminal tandem cell that reaches 25.4%, which they plan to submit to the National Renewable Energy Laboratory for certification. (NREL and the Fraunhofer Institute are among the handful of calibration laboratories around the world that provide this seal of approval for solar cells.)

Aside from the improvements in perovskite chemistry, the rapid gains in two-terminal tandem efficiency have come from a long list of modifications to the cell’s structure and the techniques used to put it together. These include switching to hole-harvesting materials that don’t inadvertently suck up any light, adding antireflection coatings to the perovskite and silicon cells, and using lower-temperature processes to create the perovskite layer to avoid damaging the silicon beneath (Adv. Mater. Interfaces 2017, DOI: 10.1002/admi.201700731).

Twenty-five percent efficiency marks an important tipping point, Stanford’s McGehee says. Currently, the small test cells used for certification boast an efficiency that’s a few points higher than whatever could be achieved by a full-size solar module of the same composition, so the levels being achieved right now don’t offer a major gain over the best commercial-scale silicon panels. “But every point after 25%, they’re getting exponentially more exciting” for the field, McGehee says.

Catchpole reckons that the solar industry will want to see more efficiency gains before commercialization of perovskite-silicon tandems becomes a realistic prospect. “I tend to think that you need to see 28–30% in the lab,” she says.

But having multiple results around 25% certainly bodes well for the future, says Jérémie Werner, part of Ballif’s team at EPFL: “Thirty percent efficiency is now just a technical challenge—there’s no reason we won’t get there.”

Commercial prospects

Oxford PV isn’t the only commercial player in perovskites. Saule Technologies is working on flexible perovskite cells; a consortium that includes Greatcell Solar, Solliance, and Panasonic is developing stand-alone and tandem cells; and several Chinese companies are in the mix. But Oxford PV holds more perovskite solar patents than any other company (Nat. Mater. 2018, DOI: 10.1038/s41563-018-0071-z), and “in the tandem arena, they’re the leaders,” McGehee says.

McGehee points out that the silicon solar industry has extremely tight margins, so companies are likely to jump on any technology that offers even a slightly better return—especially when it takes advantage of existing silicon manufacturing infrastructure. “It gives them a way to leverage what they already have,” he says.

Case believes that once customers have concluded their own tests on the tandem cells made at Oxford PV’s Brandenburg facility, the first commercial perovskite-silicon tandem cells could be installed by 2020. “This is now a technology that can genuinely outperform mainstream silicon,” Snaith says.

Mark Peplow is a freelance science writer based in the U.K.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter