Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Recycling

Nudging reaction in reverse repurposes polyurethane foam

New polymer processing method offers a path to recycle a huge class of consumer goods

by Neil Savage, special to C&EN

April 29, 2020

| A version of this story appeared in

Volume 98, Issue 17

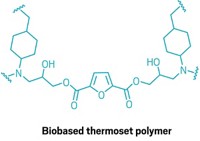

Polyurethane shows up in all sorts of consumer products: seat cushions in furniture and vehicles, car bumpers, shock-absorbing sneaker soles, and more. The global market for polyurethane was over $19 billion last year, and when those products wear out they generate vast quantities of waste—more than 1 million metric tons annually in the US alone. But the very thing that gives polyurethane its strength and durability—crosslinked polymer chains—makes it tough to reprocess into new products of comparable value. Instead of dumping it into landfills or “downcycling” it to make carpet padding, a group of researchers has shown they can break those crosslinks and reform the material to use in new products of similar commercial value to the original (ACS Cent. Sci., 2020, DOI: 10.1021/acscentsci.0c00083).

Polyurethane is a type of plastic known as a thermoset, which is cured by heat in a usually irreversible reaction. Dibutyltin dilaurate catalyzes the crosslinking reaction of the polyurethane chains as the material cures. But it turns out that at the right concentration and elevated temperatures, it both breaks and forms bonds within the material. So to break the material down, the researchers added the tin catalyst to rigid pieces of polyurethane foam and heated the material to 160° C. “We add a little bit more of [the catalyst] and that allows the reverse reaction to occur alongside the forward reaction,” says Daylan Sheppard, a graduate student in William Dichtel’s lab at Northwestern University and lead author of the paper. Because the reaction goes forward and backward, the polyurethane can be remolded.

The catalysis process breaks only a few of the crosslinks at a time, so the material never fully breaks down, Dichtel says, and the extrusion process puts mechanical stress on the material to change its overall shape. Making old polyurethane films into new films was relatively straightforward. But first attempts at reprocessing polyurethane foam into film or threadlike filaments led to cracks in the new material because of air trapped in the original foam. To combat that problem, the researchers used a pair of turning screws to force out the excess air as they extruded filaments or films.

When the team tested their method on actual consumer products, which can contain additives like flame retardants, they found such additives did not affect the reprocessing.

Steven Zimmerman, a chemist at the University of Illinois Urbana-Champaign, says the fact that researchers demonstrated the technique on commercial products is important because it shows the method can be applied to real-world materials. It’s also significant that the team recycled foams. “Previous work has focused on PU films, which are a lot easier to reprocess,” Zimmerman says. Foams “not only are most challenging but also represent the largest portion of the waste stream.” Foam is two-thirds of commercial polyurethane products.

Sheppard says producing recycled films is useful, because they’re used for rigid products such as bumpers, but given foam’s prevalence the team will work toward also making foam from the reprocessed material to broaden the types of products the process could create. They are also trying to find a more environmentally friendly catalyst without tin, Dichtel says. And they’re hoping this work might suggest new ways of dealing with other, chemically different crosslinked plastics. “The circularity of plastics really needs to improve,” Dichtel says, “and this is a small step in that very large goal.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter