Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

2-D Materials

Deicing coatings go transparent

Made of MXenes and a slippery polymer, new coating delays freezing and sheds ice in minutes under the sun

by Prachi Patel, special to C&EN

January 18, 2022

| A version of this story appeared in

Volume 100, Issue 3

A new transparent deicing coating that can also clean itself could be a boon for solar panels, windows, and windshields (Adv. Mater. 2021, DOI: 10.1002/adma.202108232).

Preventing ice buildup on car windshields and aircraft today requires spraying the surfaces with glycol-based antifreeze or deicing fluids. For a simpler, more eco-friendly alternative, researchers are developing anti-ice coatings. These include superhydrophic or super-slippery surfaces that make water roll or slip off to delay freezing. Some groups have also made surfaces that heat up electrically or by absorbing sunlight to melt ice.

Solar-heating materials are the most economical and environmentally friendly method to combat ice, says Xiaokong Liu, a chemist at Jilin University. But light-absorbing materials generally tend to be dark.

Liu and his colleagues made see-through coatings with MXenes, a recently discovered class of 2D transition-metal carbides and nitrides. They deposited alternating nanosheets of the negatively charged titanium carbide MXene and of the positively charged polymer poly(diallyldimethylammonium) (PDDA) onto various substrates. The charged layers stick strongly to each other and to the substrate via electrostatic forces. The MXene is excellent at absorbing sunlight and generating heat.

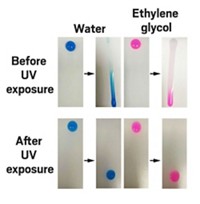

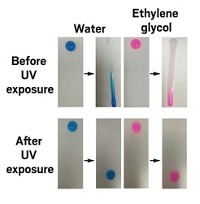

After depositing four layers each of the MXene and PDDA, the researchers coated the top with a novel transparent copolymer they made by combining 2-(perfluorooctyl) ethyl methacrylate and n-butyl methacrylate monomer units. The composite coating lets 77% of light through, appearing transparent, and the surface cleanly sheds drops of water, oil, and alcohol easily when kept slightly tilted. The team made meters-wide coatings on commercial plastic window films and glass. The coatings could easily be made on large scale for a material cost of about $ 4/m2, Liu says.

The slippery polymer helps delay freezing when the coated surfaces are wet. Ice eventually forms, but heat created by the MXene under sunlight melts the ice at the coating surface so it can slip off. When the researchers placed an ice-covered, coated glass piece outdoors on a sunny, –12 °C day, the ice slid off after 15 min.

“The coating’s durability remains to be explored in real applications,” says Zuankai Wang, a mechanical engineer at the City University of Hong Kong. But the fusion of transparent, photothermal and slippery properties is impressive and this work brings new insights in material design, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter