Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

2-D Materials

Graphene and black phosphorus get tough

Two 2-D materials team up to create a composite with record toughness

by Matt Davenport

April 10, 2020

| A version of this story appeared in

Volume 98, Issue 14

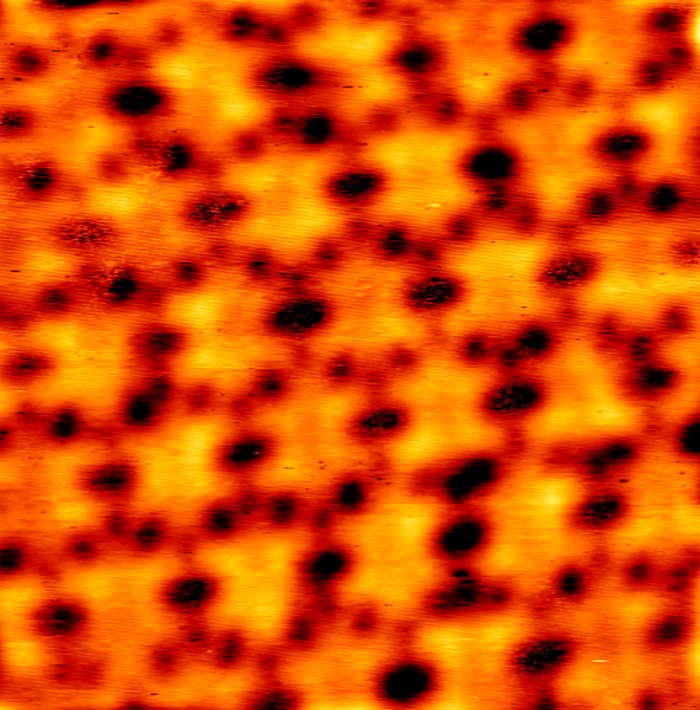

Graphene-based materials are some of the toughest composites scientists have made. Qunfeng Cheng of Beihang University wanted to know if he could make them even tougher—both stronger and more flexible—to better withstand being used as flexible electrodes in supercapacitors, for example. His team’s approach was to combine two popular 2-D materials. They brought graphene together with black phosophorus to make a composite with record-high toughness—about 1.5 times that of the next-closest graphene composite that Cheng’s team compared it against (Proc. Natl. Acad. Sci. 2020, DOI: 10.1073/pnas.1916610117). The researchers used a supramolecular linker made from 1-aminopyrene and disuccinimidyl suberate to promote stacking and alignment between graphene oxide nanosheets routinely used to make graphene composites. Adding black phosphorus creates covalent bonds, further promoting alignment and strengthening the composite. And black phosphorus acts as a built-in lubricant that helps the material flex more before it fails. The net result is a film with “extreme toughness,” says Duke University materials scientist L. Cate Brinson, who adds that the composite’s high electrical conductivity makes it a multifunctional material.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter