Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

2-D Materials

Laser method generates large films of black phosphorus

Technique could help researchers advance the 2-D material for use in high-performance electronics

by Mitch Jacoby

May 15, 2021

| A version of this story appeared in

Volume 99, Issue 18

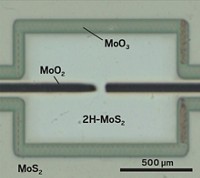

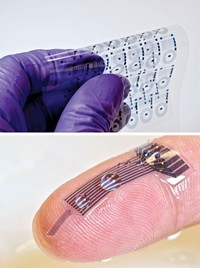

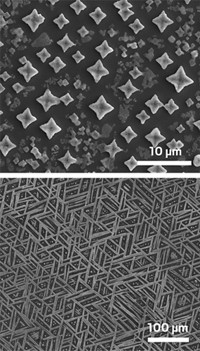

A laser deposition method can produce films of black phosphorus (BP) that are just a few atoms thick, and have areas in the square-centimeter range. The technique may provide manufacturers with a supply of the sought-after material for making fast, flexible electronic devices. A widely tunable bandgap and other useful electronic properties have made BP a standout material among 2D semiconductors, which include graphene and other materials. But BP has a size problem impeding its development: methods for making ultrathin films of the material tend to generate irregularly shaped samples with micrometer-scale lateral dimensions. Aiming to make highly uniform films large enough to be compatible with commercial fabrication methods, Zehan Wu and Jianhua Hao of the Hong Kong Polytechnic University, Xian Hui Chen of the University of Science and Technology of China, and coworkers experimented with laser ablation. They found that zapping a large BP crystal with laser light generates a high-temperature, high-pressure plasma rich in BP clusters that can settle on a nearby mica surface and coalesce to form large, uniform films just a few atoms thick. Pulsing parameters control the thickness. The team showed that the films exhibit electronic properties characteristic of BP, then used the films to fabricate working arrays containing 25 field-effect transistors (Nat. Mater. 2021, DOI: 10.1038/s41563-021-01001-7).

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter