Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

3-D Printing

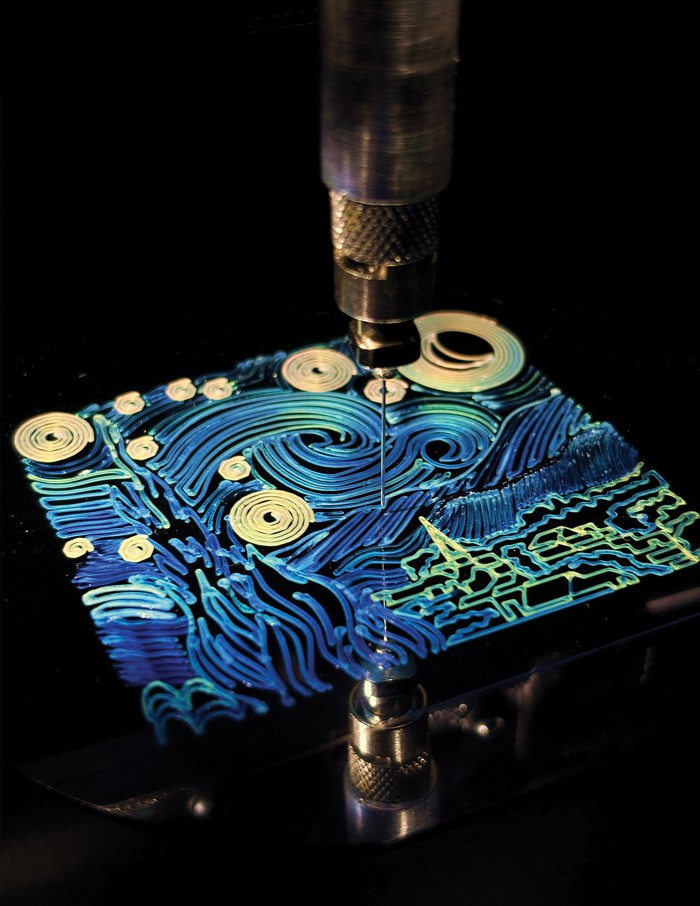

Ultrasonic waves print single drops of viscous fluids

Powerful acoustophoretic forces pull down drops of gooey substances, like honey and liquid metals

by Tien Nguyen

September 3, 2018

| A version of this story appeared in

Volume 96, Issue 35

Scientists have wielded ultrasonic waves to print droplets of liquids that are more than 1,000 times as viscous as the inks jetting from standard printers (Sci. Adv. 2018, DOI: 10.1126/sciadv.aat1659). Dubbed acoustophoretic printing by Daniele Foresti and Jennifer A. Lewis of Harvard University, Dimos Poulikakos of ETH Zurich, and coworkers, the technique offers access to a broader range of sticky substances than standard printing methods. The new method works by focusing sonic waves at the liquid-expelling nozzle to create pressures up to 100 times as great as those caused by gravity—strong enough to pull down resistant droplets. Researchers can fine-tune the droplet size (100 µm to 1 mm in diameter) by adjusting the sonic blasts’ volume, with louder volumes making smaller droplets. Using its sound system, the team created a pattern of UV-curable adhesives, deposited bioinks laced with live stem cells into 48-well plates, and printed liquid-metal electrodes made of a gallium-indium alloy on cloth. The method prints droplets as fast as ink-jet printers do by volume, the authors say. Public University of Navarre’s Asier Marzo Perez says the technique is an impressive application of acoustic radiation forces that provides a simple yet effective solution for printing bio-materials and liquid metals.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter