Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Chemistry In Pictures

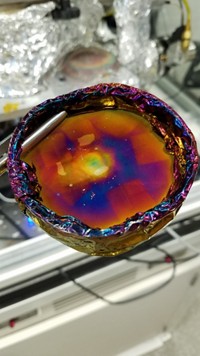

Chemistry in Pictures: Modern metallurgy

by Craig Bettenhausen

September 26, 2022

Making metals stand up to the extreme temperatures at the business end of a rocket is no mean feat. Alloys based on nickel, molybdenum, and tungsten are the main choices right now, but materials scientists are hard at work developing alloys that retain their strength and their workability so that rocket engines can be re-used repeatedly. Qinquin Wei of Hunan University and collaborators recently published a study on a two-phase tantalum carbide alloy that may be up to the task. “At high temperatures, the layered carbide skeleton carries the load,” the researchers write in a recent paper (Sci. Adv. 2022, DOI: 10.1126/sciadv.abo206). “At room temperature, on the other hand, the alloy layers buffer crack propagation, delay fracture, and promote plasticity.” These electron microscope images from the paper show how delicate the balance is; minute differences in composition lead to big changes in microstructure.

Credit: Science Advances

Do science. Take pictures. Win money. Enter our photo contest here.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter