Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Machine learning reveals new metallic glasses

Learning as it goes, algorithm could find other types of undiscovered materials

by Sam Lemonick

April 13, 2018

| A version of this story appeared in

Volume 96, Issue 16

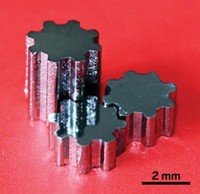

While metals tend to have a highly ordered crystalline structure, metallic glasses—unusual materials that are frequently alloys of three elements—are amorphous. That fundamental difference eliminates one of the weaknesses of metals: microscopic boundaries between crystals within the larger material. Under stress, metals can fracture at these sites, contributing to the materials’ brittleness. Also, the boundaries can serve as starting points for corrosion.

These advantages over metals make metallic glasses potentially ideal structural components, especially in corrosive environments. But despite the potential value of metallic glasses, scientists have identified only a few thousand of the materials out of estimated millions of possible alloys. A team of researchers has turned to machine learning to speed up the search and now reports three underexplored trios of elements (Sci. Adv.2018, DOI: 10.1126/sciadv.aaq1566).

Apurva Mehta of the SLAC National Accelerator Laboratory teamed up with Chris Wolverton of Northwestern University and Jason Hattrick-Simpers of NIST to develop and iteratively improve a machine-learning model that predicts alloys that will form metallic glasses. Because so few metallic glasses are currently known and there is a paucity of negative results—alloys that do not form glasses—the model had to start learning from a relatively poor data set, which hindered its accuracy. Still, the model revealed a poorly explored region of chemical space in cobalt-vanadium-zirconium alloys.

The scientists tested several thousand of the newly predicted alloys using a high-throughput technique and used that data to reinforce their model. The second-generation model was six times as accurate in predicting metallic glasses as the first. It also identified two new alloy spaces for further exploration, cobalt-titanium-zirconium and cobalt-iron-zirconium alloys. The researchers estimate that they were able to find new metallic glasses about 100 times as fast as by experiment alone.

The model takes into account not only the possible properties of alloys but also how they would be made. Techniques for making metallic glasses include sputtering atoms onto a surface, where they form an alloy, and dripping a molten alloy onto a rapidly spinning disc, allowing it to cool quickly so that a crystalline structure can’t form. Mehta explains that each technique can introduce different properties to the alloy, so an effective search must account for the production process.

Mehta says that machine learning isn’t just fast; it also draws on different kinds of information in its search, including theoretical predictions, empirical data from high-throughput tests, and even informal rules of thumb that guided past discoveries of metallic glasses. That sort of synthesis, Mehta says, is “just the way you and I learn.” He and his colleagues continue to improve their model, now on its fourth generation.

They’re also looking at how they can apply this iterative machine-learning methodology to look for other materials that are challenging to predict by theory alone. Ichiro Takeuchi, a materials scientist at the University of Maryland, College Park, sees this broader application as the real value in the new research. “Such effective integration between high-throughput experimentation and machine learning can indeed stand to change the way researchers explore new materials,” he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter