Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

New technique for injection-molding glass

Low-temperature molding of silica composite could enable rapid, inexpensive production of complex glass parts

by Prachi Patel, special to C&EN

April 12, 2021

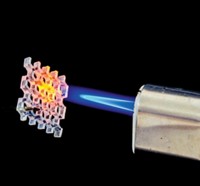

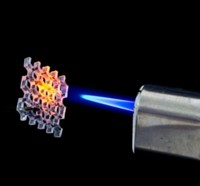

Researchers have developed a new processing technique that could enable mass production of intricate, high-performance glass objects that cost as little as plastic ones (Science 2021, DOI: 10.1126/science.abf1537). Plus, it could cut the energy use of glass processing by over 60 percent.

Glass’s optical, mechanical, and thermal properties are superior to those of plastic, and glass is fully recyclable. Yet plastic dominates the market for high-tech components like smartphone camera lenses, fiber optics elements, and medical vials because it is easy to shape and produce in large quantities.

Glass processing hasn’t changed much for hundreds of years. The material is shaped by blowing molten glass at temperatures up to 2000 °C, or casting it and then cutting, grinding, and polishing for high-performance parts like lenses. These methods are not amenable to mass production.

Plastic parts, meanwhile, are made using injection molding, which involves pouring polymers melted at much lower temperatures of around 130 °C into a mold, then cooling and removing the part. “It’s super-fast and super cost-effective,” says Frederik Kotz, a microsystems engineer at the University of Freiburg. “But glasses were so far inaccessible with this process.”

Kotz and his colleagues have found a way to blend glass and plastic processing techniques. They start with a plastic-like composite material, which they call glassomer, consisting of silica nanoparticles in a matrix of polyvinyl butyral (PVB) and polyethylene glycol (PEG).

They make the composite into pellets that resemble plastic feedstock. These pellets are compatible with a commercial injection-molding machine. The researchers mold the glassomer into various complex objects, including arrays of micrometer-scale lenses. Next, they immerse the objects in warm water for a few hours to remove most of the PEG for reuse, and then heat them for another few hours to decompose the PVB.

Sintering the objects at 1300 °C turns the material into transparent glass. Because both the molding and sintering temperatures are lower than classic glass processing temperatures, the new technique uses less energy, Kotz says. The researchers are commercializing their technology through their startup Glassomer.

Others have tried to injection-mold glass before, Kotz says, but the resulting products were whitish and opaque. Transparent glass requires a pure amorphous silica structure. To get that, the researchers start with a glassomer composite that contains a relatively high amount, over 60% by weight, of very small 50–100 nm wide silica nanoparticles dispersed evenly in the matrix. The researchers were able to incorporate such a high percentage of the silica particles in the composite by choosing hydrophilic PVB and PEG, which create a thin, even coating around the particles.

The long process required to remove the PEG and PVB from the injection-molded part is the main limitation of this technique, says André R. Studart, a materials scientist and engineer at ETH Zurich. Although injection molding itself can be take as little as 10 s, this matrix-removal process for thick parts can take up to 24 h. Nevertheless, he calls this “an important breakthrough” because it opens up a new, more sustainable way to manufacture silica glass objects..

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter