Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Video: Designer surface captures pesky bubbles

Textured metal surface could help control foams in industrial processes, like in bioreactors

by Kerri Jansen

March 2, 2020

| A version of this story appeared in

Volume 98, Issue 9

Bubbles are common in many industrial processes, including in bioreactors used to synthesize antibiotics. This foam buildup can gum up the works, and it can damage delicate cells when the bubbles burst. Chemical additives, like ones based on silicone, can reduce or prevent foam, but extra processing steps are required to remove them from the final product. Now, researchers at the Massachusetts Institute of Technology and Swiss Federal Institute of Technology (ETH Zurich) have designed a metal surface with a specially designed texture that traps bubbles and encourages them to spread out and dissipate instead of accumulating into foam (Adv. Mater. Interfaces 2020, DOI: 10.1002/admi.201901599). In lab tests, the surface reduced foam dramatically in just 10 min.

Subscribe to our YouTube channel to catch all our chemistry news videos.

The following is the script for the video.

Kerri Jansen: Sometimes foam is a good thing. But too much foam can cause problems. Foam buildup is a concern for many industrial processes, including beer brewing and water treatment. The froth can take up reactor volume, gum up filters, or even overflow. And in bioreactors, like ones used to make biologic drugs, foam forms when gases get pumped into the mix to promote cell growth. When those bubbles burst, the force can damage cells or proteins. Chemical additives, like ones based on silicone, can reduce or prevent foam. But they can require extra processing steps to remove them from the final product.

Now, researchers at MIT and ETH Zurich have designed a specially textured metal surface that can be added to bubbling mixtures to reduce foam buildup. Let’s take a look at how it works.

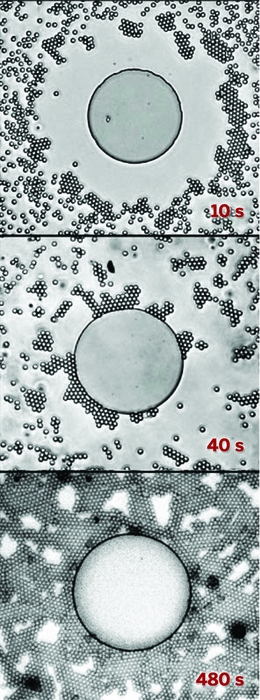

With a flat surface, bubbles bounce away several times before sticking. A surface covered with micrometer-sized silicone posts captures the bubbles slightly faster than a flat surface. The texture traps a thin layer of air along the surface, which helps spread out the gas bubbles. Adding a texture of nanometer-sized features captures the bubbles even quicker. The researchers found that adding a larger protrusion among the smaller ones helps snag bubbles on impact so that they dissipate faster. So the team combined all of these features to create a surface that captures bubbles in one one-hundredth the time of a flat surface. Then the researchers used that information to design a scalable metal device for defoaming liquids.

They mimic the micro- and nanostructures with a porous metal plate. And they mimic the protrusions by layering a fine metal mesh over top. In lab tests with a sudsy detergent solution, the porous mesh surface prevented new foam from forming and reduced foam levels dramatically in just 10 min. The researchers say the surface offers a foam-reduction alternative in applications where chemical defoamers are not feasible. They want to explore how such a surface could be extended to other applications, like capturing methane bubbles from lakes or wetlands.

Fin.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter