Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Coatings

Multifunctional material protects spacecraft in hostile environments

This thin, customizable barrier blocks heat and radiation and harvests energy

by Payal Dhar, special to C&EN

February 9, 2023

| A version of this story appeared in

Volume 101, Issue 6

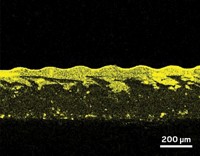

Space is a hostile environment, with huge variations in temperature and ionizing radiation that degrades spacecraft surfaces. A research team has now developed a multifunctional, lightweight skin for spacecraft exteriors that provides thermal and radiation protection and can also harvest energy. Unlike existing thermal control systems, it requires no power or bulky add-ons and can be applied in layers at room temperature (ACS Nano 2023, DOI: 10.1021/acsnano.2c09737).

The foundation of the spacecraft skin consists of a commercial water-repelling polymer with a diamond-like carbon layer on top, which makes the polymer mechanically and environmentally robust. The combination also stops water from penetrating the carbon fiber material of the spacecraft, which can affect the craft’s physical integrity, says study coauthor S. Ravi P. Silva of the Advanced Technology Institute at the University of Surrey.

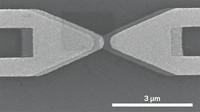

These two layers are repeated as a base; other customized layers, such as for radiation protection or solar absorption, can then be added on top. “We’ve been able to remove all of those power supplies and any sort of other extraneous additional loads that you would need,” Silva says. The researchers have already demonstrated a thermoelectric layer that measures temperature differences, and they are looking at adding solar cells.

The skin is constructed using a room temperature plasma deposition process and is less than 1 µm thick. It can be deposited onto many materials—including polymers, composites, and photovoltaics—used in spacecraft. Because it is transparent across a wide range of radio frequencies, it can be employed on sensitive structures like antennas without interfering with performance.

The paper was the culmination of 10 years of research, Silva says. The team is collaborating with the Airbus group to prepare the technology for production. Silva’s vision is that the skin will see applications beyond space travel. “Teflon, which is being used for your saucepan in the kitchen, used to be a space material that has been adopted for use in everyday activities,” he says. “So we hope that this will have a spillover to some of the more challenging areas of terrestrial use, such as trains and vehicles.”

Baratunde Cola, a researcher at the Georgia Institute of Technology who studies heat transfer, combustion, and energy systems in nanomaterials, says this material shows great potential to offer design flexibility for making systems with much lower mass and volume for space missions. In practice, he says, it is very difficult to decouple the need to reject heat from the spacecraft at low temperatures and block excessive heat absorption from the sun at high temperatures. Cola says he is also excited to see what this technology could do for thermal control of buildings and electronics in harsh environments, provided it scales at the right cost.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter