Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Electronic Materials

Flexible memory uses less power

Bendy phase-change memory material surprises researchers

by Katherine Bourzac

September 9, 2021

| A version of this story appeared in

Volume 99, Issue 33

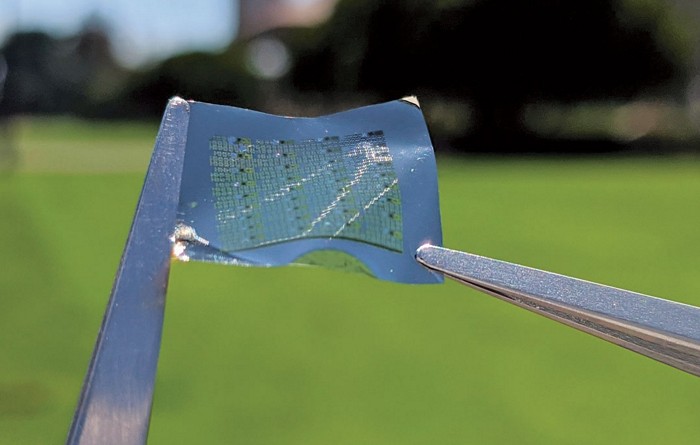

When researchers make electronics on flexible substrates, device performance typically suffers. A new, flexible version of a promising class of computer memory bucks that trend, using one-tenth to one-hundredth the power of previously reported rigid memory devices that use the same phase-change approach (Science 2021, DOI: 10.1126/science.abj1261).

Phase-change materials that reversibly switch between amorphous and crystalline states can be made into memory cells where the two phases, which have different electrical properties, represent the 1 and 0 of digital logic. Phase-change memory has been proposed as a more stable, faster-switching alternative to flash memory, which uses transistors to store electrical charges. But the high current needed to heat the material and change its phase consumes a lot of energy, so this approach remains expensive and niche. Flash, which is made relatively inexpensively and at large scales, still rules the day in cell phones and lightweight laptops.

The benchmark phase-change memory material is a glass made of germanium, antimony, and telluride (GST). For the last 10 years, researchers have been experimenting with a different configuration of GST called a superlattice. “It’s the same atoms as GST but in beautiful striped layers,” says Stanford University electrical engineer Eric Pop.

Pop’s group put arrays of memory cells made of superlattices of alternating layers of antimony telluride and germanium telluride on flexible plastic substrates. They were curious whether they could make it work—flexible memory is a key enabling technology for electronic skin, lightweight environmental sensors, and other unconventional electronics. Once grad student Asir Khan and postdoc Alwin Daus figured out how to make the materials at temperatures that would not melt the polyimide substrate, the researchers were surprised by what they found.

“The flexible substrate provides an extra advantage we did not anticipate,” Pop says. The current required to switch the flexible memory cells’ phases is 1–10% that of any previously reported phase-change memory, and the memory cells maintain their performance when the substrate is bent. After seeing the results the team was “scrambling,” Pop says. “Why is this better?” The Stanford group believes that the layers in the superlattice, as well as the insulating properties of the plastic substrate, help confine the energy applied to the memory cells, making them heat up more efficiently and spurring a phase change at lower electrical currents.

Researchers are impressed by the Stanford memory arrays’ low power consumption. “High power consumption has been the critical bottleneck” for widespread adoption of phase-change memory, says Cheol Seong Hwang, a materials scientist at Seoul National University, adding that Pop’s group has taken a major step in solving this problem. But Hwang, reached by email, says he is not convinced by Pop’s explanation of the mechanism and is exploring other possibilities in his lab.

Pop says that what matters is “it works.” His group is now working on other implementations of the superlattice memory, including versions that can switch between not just two but four or more phases, which would make it possible to store more data in the same area. This greater storage density could help phase-change technology compete with low-cost flash, Pop says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter