Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Electronic Materials

Perovskite transistors work longer with an insulator switch-up

Hafnium dioxide insulating layer brings the solar cell materials into the realm of switchable devices

by Prachi Patel, special to C&EN

November 25, 2019

| A version of this story appeared in

Volume 97, Issue 47

Perovskites have received a lot of attention as semiconductor materials for solar cells because they’re efficient, inexpensive, and easy to make. But designing transistors, the fundamental component of digital circuits, using perovskites has proven difficult, usually resulting in devices that quickly stop working. Now, by swapping out the traditional insulating material used in transistors, researchers have made ones from perovskites that work much longer than previous attempts (ACS Mater. Lett. 2019, DOI: 10.1021/acsmaterialslett.9b00357). What’s more, the devices show properties that could make them versatile components for new kinds of circuit designs.

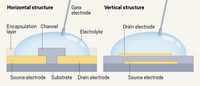

Transistors act as switches that flip between the 1s and 0s of digital logic. In these devices, a voltage applied at a gate electrode switches the flow of current on and off through a channel made of a semiconductor such as silicon. An insulating layer—traditionally silicon dioxide—protects the channel from the gate electrode voltage.

As transistor dimensions have shrunk in increasingly powerful computer chips, manufacturers have replaced the traditional silicon dioxide insulator with more insulating materials, including hafnium dioxide and hafnium silicate.

However, no one had tried these materials in perovskite transistors, so a team led by Aditya D. Mohite, a chemical and biomedical engineer at Rice University, did so, in devices with the perovskite methylammonium lead iodide as the channel semiconductor. The researchers found that changing the insulator overcame a key issue: perovskite films have structural defects that absorb some of the energy from the voltage applied at the gate electrode, making it hard for the electrode to switch the current flow precisely through the device. Applying a higher gate voltage overcomes this issue, but then the silicon dioxide insulator is unable to protect the conducting channel. So the devices degrade and stop switching after just a few cycles.

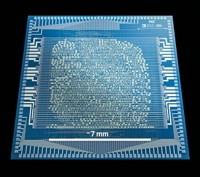

By using hafnium dioxide, Mohite and his colleagues could apply a larger gate voltage, increasing the current through the devices. The transistor could reliably switch on and off more than 100 times, whereas past devices would start degrading after just one or two cycles.

What’s more, the new device is versatile. Transistors are usually n-type or p-type—conducting either electrons or positively charged holes, respectively—but this perovskite device can conduct both types of charge carriers. A transistor that can operate in either mode would allow for smaller, more powerful integrated circuits and make circuit design much easier, says Letian Dou, a chemical engineer at Purdue University.

How the material does this a bit puzzling, Mohite says. The device starts off more p-type, but after being switched back and forth for 20 min, it becomes more n-type. After resting for another 20 min, it returns to being more p-type. “We don’t understand the mechanism, but we plan to,” Mohite says.

Perovskite transistors still have a long road ahead, though. The speed of electrons and holes in these devices is still quite low relative to silicon transistors. And the difference between the current when the device is on or off—a key parameter in transistor performance—also needs to increase by a factor of 100. But, Dou says, this first use of highly insulating materials in perovskite transistors is “a clever idea, and this direction should definitely be explored more.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter