Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Nanomaterials

Antimicrobial titanium dioxide coatings activated by indoor light

Elaborate nanostructures peppered with carbon kill bacteria under visible light

by Prachi Patel, special to C&EN

February 20, 2019

| A version of this story appeared in

Volume 97, Issue 8

Doorknobs, faucet handles, bed rails and other high-touch surfaces are the secret network germs use to spread infections in hospitals. A new coating for stainless steel could stop them in their tracks. The strong coating, which kills bacteria under visible light, is composed of intricate titanium dioxide nanostructures that give it a high surface area, and it can cover large areas (Sci. Rep. 2019, DOI: 10.1038/s41598-018-38291-y).

There is a big market for effective, low-cost coatings that can kill bacteria on hospital surfaces without contributing to the development of antibiotic resistance. Titanium dioxide shows promise. When exposed to ultraviolet light, it breaks down water vapor in the air to produce free oxygen radicals that will attack whatever is on the surface. This includes organic material, such as the membranes of bacterial cells, which is why titania is used on self-cleaning glass...

But UV-active titania coatings aren’t practical for hospital use. “The hunt has been how to shift this magic over into the visible light spectrum,” says Susan Krumdieck, a mechanical engineer at the University of Canterbury in New Zealand.

Krumdieck and colleagues grow titania coatings directly on stainless steel using a pulsed chemical-vapor deposition technique she developed. In conventional CVD, vapors of the target molecule mixed with an inert carrier gas are injected into a vacuum chamber containing the heated substrate to be coated, but this dilutes the starting material. Krumdieck’s method uses an ultrasonic atomizer to make a fine mist of a titanium dioxide precursor and sprays pulses of it into the chamber, which increases the rate at which the titania crystals grow.

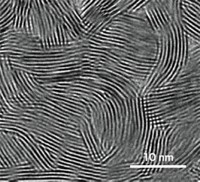

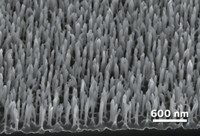

The resulting 10µm–thick coating looks black. But curious features show up under a microscope: vertical columns of stacked 15–20nm thick single crystals of titania interspersed with pine cone-like polycrystalline structures of the compound. Chemical analysis indicated that solid carbon is present on the crystal surfaces in spaces between the nanostructures. The coating has a surface area 100 times greater than previous titania coatings made with nanoparticles, which results in more bacteria-killing reactive oxygen species, Krumdieck says. The carbon helps to absorb visible-light photons, and “feeds” them to the titanium dioxide, she explains.

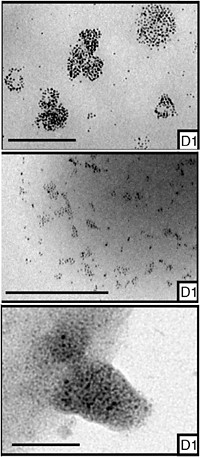

The researchers tested the coating’s antimicrobial activity by spreading E. coliculture on a sample and exposing it to UV and white light from a commercial 1500-lumen lamp for four hours. UV exposure killed all the bacteria every time, while visible light killed over 99% of the bugs. “Visible light activity is not as complete as UV but beats the international standard for antibacterial materials by an order of magnitude,” she says.

The team has coated stainless steel doors and faucet handles, and surfaces the size of a dinner plate. Krumdieck says the method should work on other metal surfaces and on glass.

The mixed-crystal structure of these new coatings is unusual, and they clearly show activity under visible light, says Sami Rtimi of the Swiss Federal Institute of Technology. But more thorough and longer-term antibacterial testing needs to be done to determine their practicality. “The 1000–fold reduction does not mean that the bacterial inactivation is total,” he says. For hospital settings, the coating would likely need to kill more bacteria and work faster, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter