Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Hollow Nanofibers in a Single Step

Electrospinning, sol-gel chemistry are combined to form nanotubular fibers

by Mitch Jacoby

April 26, 2004

| A version of this story appeared in

Volume 82, Issue 17

Follow fibers with nanometer-scale diameters can be prepared in a single step using a newly developed method. The simple and flexible technique can be used to make nanotubes from a variety of materials, leading to a host of potential applications in microfluidics, sensing, field-emission devices, and other areas.

Nowadays, chemistry and materials journals are filled with reports describing new methods for synthesizing all sorts of nanotubes. Most of the preparation techniques, especially for products other than carbon nanotubes, make use of self-assembly and template-based procedures. Although a large variety of materials encompassing a range of properties have been used, the synthesis techniques tend to be complex and involve careful design, preparation, and the ultimate removal of the nanosized templates around which the tubes are grown.

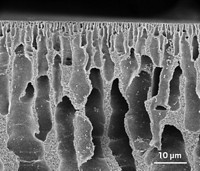

Now, researchers in Spain and the U.S. have developed a technique that yields hollow fibers with nanometer-sized interior diameters in just a single step [J. Am. Chem. Soc., 126, 5376 (2004)]. The method exploits electrohydrodynamic forces that form coaxial jets of liquids with microscopic dimensions. By the injection of two immiscible—or poorly miscible—liquids through a pair of concentric needles to which a high voltage is applied, the liquids emerge from the needles coaxially: a tiny interior stream of one material surrounded by a shell of the other. The shell solidifies around the interior liquid, which serves as a simple template and evaporates once the fibers are collected.

The new technique was used to spin hollow silica fibers with fairly uniform-sized inner diameters measuring a few hundred nanometers. The shells were formed via sol-gel chemistry from tetraethylorthosilicate around cores of common liquids such as olive oil and glycerin.

The research team includes Ignacio G. Loscertales of the University of Málaga; Antonio Barrero of the University of Seville; Manuel Márquez of Los Alamos National Laboratory; Gustavo Larsen of the University of Nebraska, Lincoln; and their coworkers.

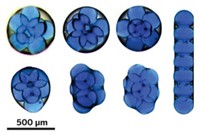

The work builds on an earlier study by the team in which they showed that electrohydrodynamic forces could, in fact, be used to form steady coaxial liquid jets with micrometer-sized or even smaller diameters. The technique was used to form aerosols of core-shell droplets of uniform size [Science, 295, 1695 (2002)]. Márquez explains that product morphology (sphere versus tube) and other characteristics, such as diameter and wall thickness, are readily controlled by selecting reagents with suitable surface tension and viscosity and by adjusting flow rates and voltages.

“It’s an elegant approach to creating hollow nanotubes via ‘liquid templating,’ ” remarks Jennifer A. Lewis, professor of materials science and engineering at the University of Illinois, Urbana-Champaign.

Harvard University physics professor David A. Weitz agrees with Lewis’ assessment. Both scientists comment that the technique is open to wide-ranging chemical possibilities and is sure

to extend to a variety of materials.

The electrospinning method has also been used by chemists at the University of Washington, Seattle. In that study, Younan Xia and Dan Li prepared hollow composite nanotubes of poly(vinylpyrrolidone) and titania as well as nanotubes made just from titania. The tubes were formed around cores of mineral oil that were later removed with solvents or heat treatment [Nano Lett., published online March 30, http://dx.doi. org/10.1021/nl049590f].

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter