Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biological Chemistry

One-Pot Biodiesel

Synthetic Biology: Bacteria make biodiesel directly from glucose and hemicellulose

by Celia Henry Arnaud

February 1, 2010

| A version of this story appeared in

Volume 88, Issue 5

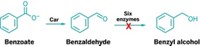

A bioengineering development could lead to a cheaper route to products derived from plant biomass. Researchers have redirected fatty acid metabolic pathways in the bacterium Escherichia coli to produce biodiesel and other chemicals such as fatty alcohols, aldehydes, and wax esters directly from glucose (Nature 2010, 463, 559).

“My goal has been to produce the kinds of fuels that will work with our existing transportation infrastructure,” says Jay D. Keasling of the University of California, Berkeley, who carried out the work with Stephen B. del Cardayre of the industrial biotech company LS9, located in South San Francisco, and coworkers. “We’re at the point with biology where we can engineer the biology to work with our existing infrastructure rather than vice versa,” Keasling adds.

To do that, his team engineered bacteria to produce long-chain fatty acid esters that can be used as biodiesel. The researchers increased the amount of free fatty acid by engineering the bacteria to express a thioesterase enzyme that releases the fatty acid from the carrier protein to which it’s normally tethered. By doing so, and by suppressing other enzymes that compete with the formation of fatty acids, the researchers boosted the bacteria’s output of the acids three- to fourfold.

Making fatty acid ethyl ester, which can be used as biodiesel or as a precursor to other chemical products, requires the simultaneous expression of an ethanol-producing metabolic pathway. The fatty acids and the ethanol need to be made in the right ratios, Keasling says. “If either one of them is limiting, then it’s going to limit the production of the final product,” he says.

They were able to efficiently produce the esters with glucose as the sole carbon source. By adding a pathway to produce enzymes that degrade hemicellulose, a structural material found in plant cell walls, the researchers demonstrated the production of biodiesel using hemicellulose as a feedstock.

“If feedstock availability, large-scale production, economics, and product properties are favorable, this approach may have the potential of significantly increasing the supply of biofuel,” says Gerhard H. Knothe, a biodiesel researcher with USDA’s Agricultural Research Service in Peoria, Ill.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter