Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Polymer Passes Up N2 For CO2

Azo groups are key for keeping nitrogen at bay

by Bethany Halford

January 21, 2013

| A version of this story appeared in

Volume 91, Issue 3

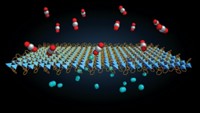

Although scientists have come up with many materials for soaking up excess carbon dioxide, most have drawbacks that keep them from ever leaving the lab. In the case of organic nanoporous polymers, the problem is that as temperatures rise, these materials have trouble differentiating CO2 from nitrogen gas. Now a team led by Cafer T. Yavuz and Ali Coskun of Korea Advanced Institute of Science & Technology has come up with polymers that get better at separating CO2 from N2 as they get hotter (Nat. Commun., DOI: 10.1038/ncomms2359). The nanoporous polymers feature aromatic groups bridged by azo units. The researchers believe that these azo units make the materials N2-phobic. “Any gas separations that require the efficient exclusion of N2 gas would do well to employ azo units in the sorbent chemistry,” they note. The polymers are stable up to 350 °C in air and can also survive a boiling water bath for a week. They are particularly good at keeping out N2 under typical industrial plant gas-discharge temperatures of above 40 °C.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter