Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Flame-Retardant Graphene Foam Fights Fire With Carbon

2-D Materials: Ultralight foam possesses properties that make it attractive for aerospace applications

by Bethany Halford

January 25, 2016

| A version of this story appeared in

Volume 94, Issue 4

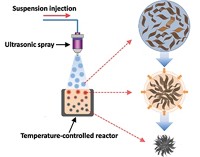

Halogenated flame-retardant materials have come under fire in recent years because of concerns they have negative health and environmental impacts. Knowing that graphene has worked well as a flame-retardant additive for polymers, researchers in China and the U.S. wondered if they could make a fire-resistant material composed primarily of the carbon allotrope. A team led by Liangti Qu of Beijing Institute of Technology and Liming Dai of Case Western Reserve University prepared an ultralight foam made of graphene and phosphorus oxide and phosphorus nitride nanoparticles (ACS Nano 2016, DOI: 10.1021/acsnano.5b06710). The scientists prepare the flame-retardant material by mixing a graphene oxide solution with hexachlorocyclotriphosphazene and turning the blend into foam via a freeze-drying process. This method, they note, has the advantages of being simple, scalable, and environmentally friendly. They then expose this material to a flame, which transforms the graphene oxide into graphene and eliminates chlorine from the material. The resulting foam outperformed flame-retardant polymers, metallic oxides, and metal hydroxides in tests. What’s more, the foam is a lightweight absorber of microwave radiation, which makes it promising as a radar-shielding material in commercial or military aircraft.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter