Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Investment

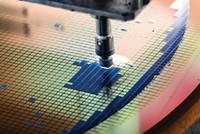

Fujifilm to spend $350 million on US electronic material business

Boost to production capacity, R&D, will support semiconductor industry customers

by Craig Bettenhausen

July 23, 2022

| A version of this story appeared in

Volume 100, Issue 26

Fujifilm’s electronic material division plans to spend $350 million in the US by March 2024 to expand production and grow its R&D prowess. The move is part of a $1 billion global investment by the specialty film and chemical maker in response to new semiconductor fabrication plants planned by firms including Samsung, GlobalFoundries, Taiwan Semiconductor Manufacturing, Intel, and Texas Instruments.

Brian O’Donnelly, CEO of Fujifilm Electronic Materials USA, says the global semiconductor market is expected to reach $1 trillion annually by 2030. Fujifilm aims to almost triple its sales to the industry, to $3.3 billion per year, over the same period, led by materials for lithography and chemical mechanical planarization (CMP). The firm has US plants in Arizona, Rhode Island, Texas, and California.

O’Donnelly says the investment will be split between those four facilities, each of which also has an R&D hub. The firm is already hiring chemists and chemical engineers as part of the expansion. “I’m excited, we’re all excited, and I think there’s great opportunities to work with us because the growth trajectory is very positive,” he says.

Chemical firms with a presence in electronic materials are building US capacity quickly to meet the expected demand from semiconductor makers for localized supply. In December, for example, Merck KGaA announced a $1 billion investment plan for its US electronics division. The electronic chemical maker Entegris completed its acquisition of the Illinois-based CMP slurry maker CMC Materials on July 6.

Mike Corbett, a managing parter at Linx Consulting, says the investments and deals that are already public will probably cover a lot of the new demand for lithography and CMP supplies, as well as for specialty gases. At the same time, supplies of high-purity process chemicals may have some catching up to do, and the market has room for more competition. “I would expect there to be more announcements,” Corbett says. “I don’t think we’re quite done yet.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter