Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Physical Chemistry

Making molecular movies at Europe’s powerful X-ray laser facility

Although some kinks are still being worked out, the European XFEL is now giving researchers an unprecedented view of the inner workings of molecules and materials

by Mark Peplow, special to C&EN

July 21, 2018

| A version of this story appeared in

Volume 96, Issue 30

“Tough day,” sighs Allen M. Orville, shaking his head. The biophysicist is standing in the vast underground experiment hall of the European X-ray Free-Electron Laser (EuXFEL) facility near Hamburg, Germany, at the end of a 12-hour wrestling bout with the biggest, brightest X-ray source on the planet. For now, the machine appears to be winning.

Orville leads a group at the U.K.’s Diamond Light Source that develops hardware and software for EuXFEL and also supports researchers who bring their samples here. Today, he’s with an international team studying the mechanics of two particular enzymes: One of them makes antibiotics, and the other breaks them down. Understanding exactly how they work could help scientists develop better antimicrobial drugs.

To watch the enzymes in action, the researchers are focusing—or at least attempting to focus—EuXFEL’s intense X-ray pulses so that they produce a series of structural snapshots of the biomolecules, rather like high-speed flash photography. Stringing these snapshots together produces a “molecular movie” that could reveal how the reaction mechanisms play out.

A brilliant plan

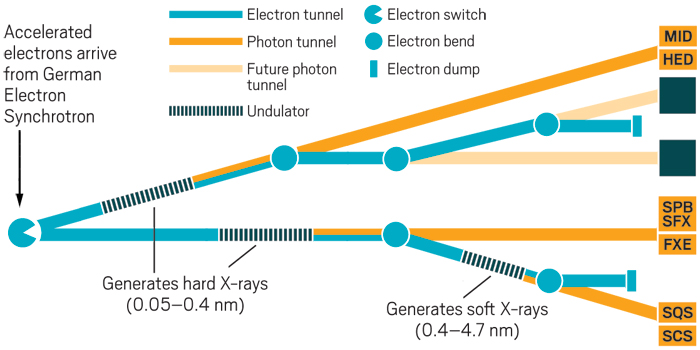

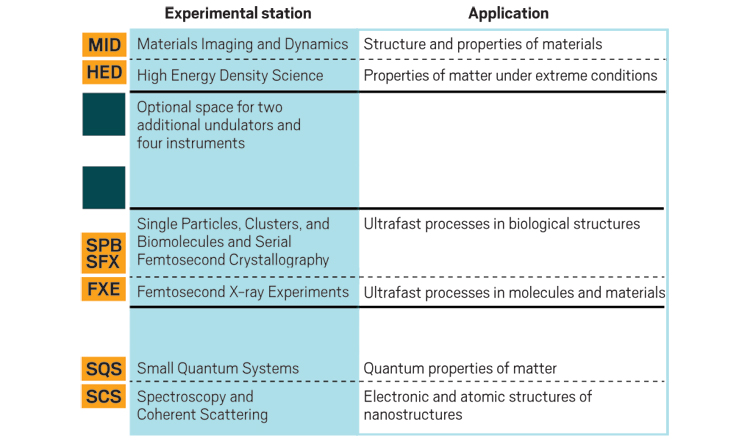

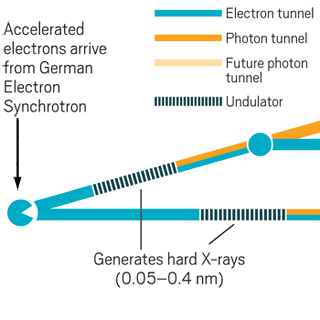

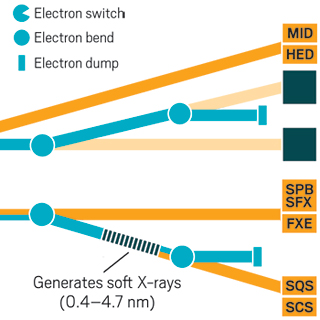

As shown in this map of EuXFEL, the facility generates X-ray pulses that travel through underground tunnels and feed an array of current and future instruments at the facility.

Only things haven’t been going as planned. The micrometer-sized enzyme crystals that Orville and the rest of the team are streaming into the instrument keep missing the X-ray pulses, and the crystals are also clogging the injector’s nozzle.

EuXFEL joined a small family of other X-ray free-electron laser facilities operating across the globe when it opened its doors to external users in September 2017. Like any other enormous, highly advanced scientific facility, it has faced its share of growing pains. Fixing problems with equipment and software is a natural part of the commissioning phase at most X-ray facilities, when operators test and install components. Unusually, though, EuXFEL has adopted a “user-assisted commissioning” approach, so in-house scientists are still ironing out glitches at the same time external users are arriving to gather data on their samples.

At other facilities, the commissioning “all happens behind the curtain, sort of like the Wizard of Oz,” Orville says. “I don’t know of any other facilities that have had such a large number of users during the earliest commissioning phase.”

Most users are willing to tolerate the inconvenience because they’re getting early access to a world-class facility. Over the past decade, XFELs in places like California and Japan have enabled scientists to explore the molecular systems responsible for photosynthesis, study proteins involved in diseases like Alzheimer’s and cancer, and probe the magnetic properties of digital-memory materials. And they do all this with atomic precision, at the femtosecond timescale (10–15 seconds, or quadrillionths of a second). “That’s the timescale where chemistry and biology and materials science happen,” says Mike Dunne, director of the Linac Coherent Light Source (LCLS), an XFEL at the SLAC National Accelerator Laboratory, in California.

Not only does EuXFEL save users in Europe from having to travel so far to enjoy those capabilities, but the facility is also a huge advance for X-ray technology in general: Running at full tilt, it should deliver 27,000 pulses per second, hundreds of times more than other XFELs. More pulses mean more data, enabling researchers to image complex structures faster than ever before. “It’s a big leap forward,” Dunne says.

Petra Fromme of Arizona State University was among the first users at EuXFEL last year. She thinks the facility’s unique user-assisted commissioning strategy is the right approach. “Users come in with good ideas and experience from other XFELs, and EuXFEL can draw on all that expertise,” Fromme says. “It’s much better than relying on a small team that tries to fix everything.”

But it can also lead to some frustrating battles with the new technology. “It is a lively, complex animal, and we’re learning every day about its little hiccups,” says Christian Bressler, lead scientist for EuXFEL’s Femtosecond X-ray Experiments (FXE) instrument. After a day of coaxing recalcitrant hardware to rattle off X-ray pulses or cleaning up buggy software, it can feel like the pain of commissioning will never end, he says. “The question that is now making us shuffle our feet a little nervously is: When will this stop?”

It’ll be worth it, though, because EuXFEL will allow researchers to watch how chemical processes unfold in unprecedented detail. “Once we get there, that’s an electrifying moment,” Bressler says.

Settling in

Construction of EuXFEL began in 2009, with Germany and Russia contributing more than 80% of the €1.2 billion ($1.4 billion) in costs and 10 more European nations making up the rest. The facility is open to researchers around the world, with access determined by a committee that reviews experiment proposals, and beam time is free of charge. More than 300 users have already visited the facility, some from as far afield as India, China, and Argentina.

Like synchrotrons, XFELs can produce “hard” X-rays with wavelengths around 0.1 nm, or 1 Å, small enough to resolve the positions of individual atoms. Synchrotrons typically produce pulses lasting a few tens of picoseconds (10–12 seconds), but an XFEL’s pulses are much briefer, allowing them to freeze-frame atomic action. XFELs are also 1 billion times as bright, enabling them to produce clear structures using much smaller, nanoscale crystals or even clusters of molecules that refuse to crystallize.

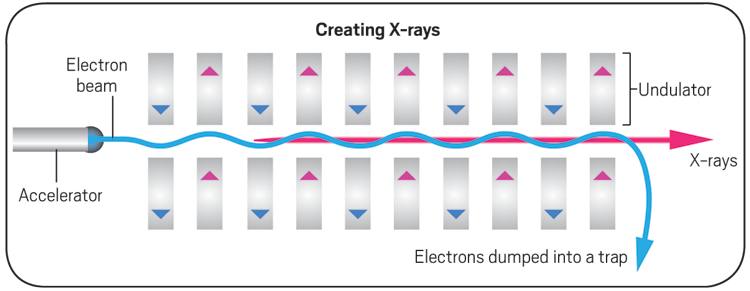

The process that generates EuXFEL’s pulses starts 3.4 km away at the German Electron Synchrotron center, which uses the longest superconducting linear accelerator in the world to spur electrons almost to the speed of light. As they fly along underground tunnels, the electrons slalom through a series of powerful magnets called undulators, which force the particles to emit bursts of X-rays. In a self-amplifying process, those X-rays make the electrons bunch up and release even more X-rays that are all in phase with each other, forming coherent pulses around 100 femtoseconds long.

The whole machine is incredibly finely tuned. The electron beam has to be aligned to within a few micrometers as it hurtles through the undulators in order for the system to work properly. And EuXFEL’s recent building work doesn’t help: The facility is literally settling in, with the ground here shifting by several millimeters per year, so the machine requires constant readjustments. “We hope that this will become better over time,” says Harald Sinn, who leads EuXFEL’s X-ray optics group.

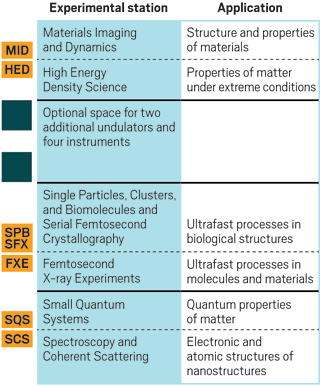

EuXFEL is laid out so that the central electron beam splits into three lines that ultimately deliver X-rays to various experimental stations spread around a subterranean room the size of an American football field. So far, the facility has one operational beamline feeding two stations: the FXE instrument and the Single Particles, Clusters, and Biomolecules and Serial Femtosecond Crystallography (SPB/SFX) instrument, which Orville’s team is using. Both instruments sport optical lasers that can pump femtosecond shots of light into a sample to trigger chemical changes. By adjusting the timing between the light and the X-ray pulses, these “pump probe” experiments can capture a molecule at different points in a reaction.

Later this year, a second beamline will begin supplying lower-energy “soft” X-rays to two instruments dedicated to quantum systems and phenomena such as high-temperature superconductivity.

In 2019, a third beamline will deliver hard X-rays to another pair of instruments. One will look at matter under extreme conditions of temperature and pressure, and the other will study the properties of materials, including their magnetic behavior.

When hard X-ray photons hit a sample in an instrument like the SPB/SFX, they completely obliterate the target molecules. But in the instant before they cause the destruction, some of the photons diffract into a pattern that bears an imprint of the sample’s molecular structure. An X-ray camera—the ones at EuXFEL typically boast 1 million pixels—records the scattered photons, producing a tsunami of diffraction data that can be reconstructed into a three-dimensional molecular model. EuXFEL’s “detectors don’t exist anywhere else on this planet, cameras so fast they can record full X-ray images five times in a millionth of a second,” Bressler says. “That’s just breathtaking.” By 2020, when it will be fully operational, the facility should generate at least 10 petabytes of data per year.

Each pulse can perform a single diffraction experiment, but researchers may need to compile tens of thousands of these miniature snapshots to discern a molecule’s structure. EuXFEL’s high pulse rate means that it can gather data in minutes that would take days or even weeks at other XFELs, Sinn says.

Advertisement

Visiting researchers need to work closely with EuXFEL’s house scientists, who are on hand to jockey the instruments and ensure that no accidents occur with the beam. “It’s pretty dangerous,” Bressler says. With an XFEL beam, “you can drill through thick plates of metal, no problem.” That’s a marked contrast to less powerful synchrotrons, where users can fly solo with relatively little training. Working at a synchrotron facility is like driving at a go-kart track, he says. “They put you in the car and say, ‘This is the brake, the gas pedal, and the steering ... see you later.’ ” With XFELs, it’s more like flying a fighter jet—everyone needs an experienced copilot.

Catching the train

It’s just past 8 PM in Hamburg, and Orville’s team has gathered with the SPB/SFX house scientists to review their difficult day and plan a strategy for tomorrow. After an intense 12-hour shift, there are a lot of tired faces around the room, interspersed with anxious ones compulsively chewing gum. “Fatigue is a huge issue,” Orville says. “You can easily have a mistake with the equipment.”

He fields ideas from the group, comparing the pros and cons of various options to reach a consensus about what to do next. Since they have only two of their four shifts left on the instrument, it’s vital that they make the right decision.

Managing the expectations of his visiting researchers is a key part of Orville’s job; so too is ensuring that the in-house scientists are invested in the research problem under investigation. “I really feel for the beamline scientists because they’re still learning how to drive a very complicated system, and there’s a lot of people looking over their shoulders hoping for the best,” he says.

Orville’s team wants to figure out exactly how β-lactamase enzymes degrade certain antibiotics, a key process in antibiotic resistance. The researchers are also studying isopenicillin N synthase (IPNS), which builds penicillin-based antibiotics using a four-electron oxidation process that relies on a transient iron(IV) center in the enzyme. Producing a molecular movie of both processes could help researchers develop more effective antibiotics that break through the defenses of resistant microbes.

The researchers have prepared slurries of enzyme crystals, which they spurt into the path of the X-ray pulses. That should provide structures of the enzymes in their resting states. Later, they’ll add the substrate for each enzyme to the mix to see how it fits into the enzyme’s active site and record how the reaction progresses.

So far, they haven’t made much headway. The jet of crystals has been jerking around like a bucking bronco, making it difficult to align with the X-ray pulses, and the nozzle of their sample injector keeps getting blocked. The team has collected a modicum of data but not enough snapshots to piece together the full picture of the enzymes in their resting states. Still, the problems are far from unprecedented: “I’ve been to every single XFEL facility, and sample delivery is a challenge at every one of them,” Orville says.

But EuXFEL’s unique X-ray pulses present an additional complication. Rather than produce a continuous stream of evenly spaced X-ray pulses, as is done at other XFELs, this facility’s pulses are clustered into “trains,” with a long gap of 99.4 milliseconds in between, when there are no pulses at all. The plus side of this setup is that the pulses within each train will arrive at a formidable 4.5 MHz, far surpassing the 60–120 Hz pulse rates of other XFELs and providing many more diffraction snapshots. The minus side is that coordinating a sample stream with those pulse trains is extremely difficult.

In fact, it’s not currently possible to turn the sample jets on and off during the gaps between pulse trains, so the vast majority of precious microcrystals go to waste. “It’s a challenge for everybody to adjust to this pulse pattern,” EuXFEL’s Sinn says. In the future, Orville and his colleagues hope to avoid this problem with a system called acoustic droplet ejection, which uses focused sound waves to control the delivery of nanoliter sample droplets into the path of the X-ray trains.

Meanwhile, Alexandra Ros at Arizona State University is also developing a solution to the pulse train problem. During her visits to EuXFEL, she has been using the SPB/SFX instrument to test a microfluidic system that can deliver sample droplets on demand. It carries crystals in small bubbles of water that are trapped within a stream of oil flowing through a capillary. By adjusting the speed of flow, the aqueous droplets deliver their precious cargo just as a pulse train arrives. Ros has bid for more time at EuXFEL to refine her method and hopes to show that it can tackle a wide range of samples. “We want to make our system as generic as possible,” she says, so that other EuXFEL users can use it for their own samples.

Despite all these challenges, users are still doing plenty of good science. Last year, Ros’s ASU colleague Fromme brought a team to EuXFEL to study photosystem I, the complex of proteins and cofactors that nature uses to turn light into chemical energy during photosynthesis. They gathered enough data with the SPB/SFX instrument—about 60,000 images—to resolve the structure of photosystem I just after being activated by light. The team will return in August to complete a data set that images the complex just before excitation. Filming the full sequence of events could guide efforts to develop artificial photosynthesis systems, Fromme says.

And the ASU researchers aren’t the only EuXFEL users who’ve had success at the facility. “I’m very proud to say that with all of the user-assisted commissioning experiments at my instrument, we’ve sent them home with some data,” says Adrian P. Mancuso, lead scientist for SPB/SFX at EuXFEL.

Perhaps tomorrow will bring Orville’s team more luck.

Bug hunt

As Orville wraps up his strategy meeting, Grigory Smolentsev is just starting work at the FXE instrument on the other side of the experiment hall. Rather than using EuXFEL to explore biomolecules, the Paul Scherrer Institute scientist is directing the facility’s X-ray pulses at a materials science problem: He’s studying a copper-organic complex that could improve the efficiency of organic light-emitting diodes (OLEDs).

The simplest OLEDs use an electric current to excite an electron within an organic semiconductor, leaving behind a positively charged “hole.” When that electron relaxes, it releases a photon of light. While excited, the electron and hole can either have the same spins and exist in a triplet state or have opposite spins and exist in a singlet state. But only the singlet state can emit a photon rapidly through fluorescence, fundamentally limiting the device’s efficiency. The copper compound, developed by Matthias Vogt at the University of Bremen, allows triplet states to convert into singlets, boosting light output.

Smolentsev is using X-ray emission spectroscopy to track changes in the copper-organic complex’s electronic properties at the same time as wide-angle X-ray scattering reveals any structural differences between singlet and triplet states. That should help Smolentsev’s colleagues fine-tune the material’s composition to boost its efficiency. Catching it in the act with EuXFEL’s X-ray pulses will be no mean feat, though, because the singlet state exists for only 10 picoseconds. “That’s why it’s impossible to capture these states with a synchrotron,” Smolentsev explains.

This is Smolentsev’s second stint at EuXFEL. His first visit last year was stymied by technical problems. Some of those glitches were due to the facility’s instrument control software, which among other tasks labels every single chunk of data so that it can be traced back to a specific pulse. “The software is brand new and it’s full of bugs,” Bressler says. “It drives you freaking nuts when you know that you are a victim of technology development. But we are getting better every day.”

That certainly seems to be the case for Orville’s team. Overnight, the researchers prepped new sample injectors to avoid the clogging problems they had yesterday, while the SPB/SFX scientists directed some strobe lighting at the sample chamber to see precisely where the sample jet was in relation to the X-ray beam. “We found the stream much, much quicker today than yesterday,” Orville says. The team has already collected some data from the IPNS enzyme in its resting state and is about to add the biomolecule’s tripeptide substrate to watch the pair bind and react.

Inside the SPB/SFX control room, a dozen or so researchers are sitting in front of computer screens that display details of the X-ray pulses, the sample jet, and a host of other parameters. Six more sit in a small annex, adjacent to a table loaded with vital supplies of tea and coffee. Here, researchers can analyze data on the fly so they can get a sense of whether an experiment is working.

At the other end of the control room is the experimental hutch, its thick metal sliding door standing open while scientists flit in and out, tweaking and testing and checking the equipment inside. The beam of X-ray pulses is currently more than 10 µm wide, and the researchers are trying to focus it much tighter, to less than 3 µm, to produce sharper snapshots of their samples.

The SPB/SFX instrument itself is roughly the size of a family car, a complex collision of stainless steel pipes, wires, and flexible tubing that can be intimidating for new users. “Touch the wrong thing at the wrong time, and you break it,” Orville says.

Some of his team members are upstairs, where EuXFEL has pristine labs for scientists to prepare and characterize their samples. Some areas are so new that bubble wrap still covers the benches, and the sinks gleam. A dumbwaiter sits ready to carry samples from the labs directly down to the control room area.

One of the benefits of user-assisted commissioning is that external researchers can help EuXFEL decide what lab equipment is needed to enable any visitors to use their allotted beam time—sometimes only a handful of hours once or twice per year—most efficiently. They also help get that equipment running, bringing unique skills that EuXFEL may not have in-house. For example, Orville’s team is involved in commissioning a brand-new anaerobic chamber in the labs upstairs, which is essential for handling air-sensitive samples. “Some XFEL facilities don’t have anything close to an anaerobic chamber; some places even forgot to include a sink,” Orville says. “This is the first place that I’ve seen that has such a holistic approach.”

Taking stock

The true test of EuXFEL will be the science it produces, and Thomas Tschentscher, one of the facility’s scientific directors, says that the first papers from users should be out in the next few months. “We had a tough time last year to get everything running, and there was also a lot of frustration that things did not run so well,” he concedes. “But now we are in a more stable situation; things are much better.”

So far, most of the external researchers who’ve come to EuXFEL during its commissioning phase have been experienced XFEL users. But Tschentscher is eager to broaden the user base to include people with no such experience who nevertheless have scientific problems that the facility could help solve. “These are the new communities that are really interesting to us,” he says. EuXFEL is trying to drum up interest through conferences and widely publicized calls for proposals, but Tschentscher thinks that task will be a lot easier once the facility can prove its worth through a body of published work. “In the future, I very much hope that we can have users who will expect everything to just work out of the box,” EuXFEL’s Mancuso says.

Meanwhile, California’s LCLS is also getting a $1 billion upgrade that should come on-line in the early 2020s. LCLS II will be able to generate up to 1 million pulses per second, which can be clustered into trains or run continuously, says Dunne, the facility’s director. The upgrade will end EuXFEL’s reign as the most sophisticated XFEL. Over in China, construction of a hard X-ray XFEL began in April, and Tschentscher expects the country to build more. If there’s any rivalry between all these facilities, it’s pretty friendly. LCLS sent a team to EuXFEL during early commissioning, for example, to offer assistance and bring back valuable lessons that will feed into LCLS II.

Several weeks after visiting EuXFEL, Smolentsev is still sifting through his team’s results. “We got quite a lot of data, but we see something different from what we expected,” he says. “We need time to understand whether we have learned something new about our OLED materials or only something about XFEL experiments.”

Back in the U.K., Orville and his colleagues are also taking stock. They managed to gather enough data to show the structure of IPNS at three stages of the enzyme’s reaction with its substrate but are still figuring out whether they’ve captured the entirety of the mechanism—the before, during, and after of the reaction. They suffered no more major problems but never managed to get the X-ray pulses as tightly focused as they would have liked. “That’s just the way it goes,” Orville says. “We’re still on the frontiers, trying to figure out the right solution to the things that we encounter.” He has already submitted proposals to go back to EuXFEL for more data.

Mark Peplow is a freelance science writer based in the U.K.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter