Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Hydrogen Power

Turning organic waste into hydrogen

Researchers are using bacteria to transform various types of waste into a clean-burning fuel

by XiaoZhi Lim, special to C&EN

April 7, 2019

| A version of this story appeared in

Volume 97, Issue 14

A narrow tower two stories high sits behind chemical engineer S. Venkata Mohan’s lab at the Council of Scientific and Industrial Research’s Indian Institute of Chemical Technology. Every other day for 6 months in 2017, he and his team fed this “beast.” They collected food waste from the institute’s cafeteria, ground it up, filtered out large particles, drained the oils, and added it to the tower, which contains an anaerobic digester filled with a soup of waste and bacteria. Munching on the leftover lunch, those microorganisms didn’t produce a conventional biogas, the typical output of digesters. With some scientific innovation from Mohan and his team, the microbes instead produced a gas rich in hydrogen. Building on the beast’s ability to pump out 5 kg of hydrogen per day, Mohan is now in talks with Indian officials to build similar plants 10 times as large to treat municipal waste in Delhi and Mumbai.

Mohan is among a small group of researchers around the world who are finding that various organic waste streams—such as food waste, agricultural waste, and wastewater—can be viable sources of hydrogen gas. These researchers seek to generate hydrogen, a fuel that does not produce greenhouse gases when burned, while simultaneously dealing with a growing waste problem. In some cases, these methods enjoy a bonus of producing valuable carbon-based products instead of climate-warming carbon dioxide.

“It hopefully will be, in the longer term, a process where we can remove waste, make a fuel, and also make value-added chemicals,” says Erwin Reisner, a chemist at the University of Cambridge.

Investing in hydrogen

Other clean technologies such as electric-car batteries are stiff competition for hydrogen in the transportation sector. But the fuel remains relevant, particularly for long-distance travel.

India faces some of the world’s worst vehicle-induced smog, but it’s not the only country interested in hydrogen. The governments of South Korea, France, and Switzerland announced renewed commitments last year to building a hydrogen economy. Japan has invested ¥40 billion ($348 million) in building hydrogen infrastructure for the 2020 Summer Olympics in Tokyo, hoping to enjoy its legacy after the games are over. Germany launched the world’s first hydrogen-powered trains last fall, a pair traveling a 100 km route in northern Germany. And California is building a hydrogen-fuel-cell ferry to serve the San Francisco Bay Area.

Even though demand is strong for clean hydrogen fuel, current production of commercial hydrogen creates its own pollution problems. Ninety-six percent of commercial hydrogen comes from steam reforming of natural gas, which produces CO2 along with hydrogen. For the hydrogen economy to be truly clean, hydrogen must come from a non-fossil-fuel source. Otherwise, “you are just shifting the [CO2] burden upstream” from vehicle tailpipes, where hydrogen is burned, to the plants where hydrogen is made, says Qiang Dai, a researcher at Argonne National Laboratory who specializes in life-cycle analysis.

Currently, the tiny market for renewable hydrogen is dominated by water electrolysis, the electrochemical process of splitting water into hydrogen and oxygen. But it requires plentiful fresh water and renewable electricity at large scale to be green and practical, which limits it to places like Iceland that have excess geothermal energy.

In contrast, waste produced by humans is everywhere—and it can be a “very valuable material,” Mohan says. In remote areas without electricity, he says, hydrogen produced from waste can power mobile homes and hospitals. Hydrogen is also a valuable chemical that is useful for chemical reactions and processes in industry. “It’s the perfect reducing agent,” says Zhiyong Ren, a chemist at Princeton University.

In 2004, Mohan was working with anaerobic digesters when he realized that turning waste into biogas, which is mostly methane, is a flawed strategy. Burning methane produces CO2, which ultimately gets lost to the atmosphere. “We’re losing a lot of resources,” he says. That carbon could be going into making other chemicals instead.

Typical anaerobic digestion uses a mix of acidogenic and methanogenic bacteria that naturally occur together in food waste to turn organic compounds into methane. The acidogenic bacteria generate hydrogen and short-chain carboxylic acids from the food, along with small amounts of CO2. The methanogenic bacteria in turn convert the hydrogen, carboxylic acids, and CO2 into methane. But the acids produced in the first step—acetate, propionic acid, and butyric acid among them—are valuable as feedstocks, and if those chemicals and the hydrogen could be preserved, it would help make hydrogen more cost competitive as a fuel.

So Mohan set out to arrest the digestion process to make hydrogen the main product by inhibiting the methanogens. For close to a decade, Mohan tinkered with bacterial populations in digesters, steering them by varying the organic content of food waste, pH, temperature, and other parameters. He found that exposing the bacterial culture to acid before digestion helps reduce the population of methanogenic bacteria, tripling hydrogen production (RSC Adv. 2016, DOI: 10.1039/c5ra24254a).

Hydrogen from the farm

Pin-Ching Maness at the National Renewable Energy Laboratory has been looking at a source of hydrogen further up the food chain: agricultural waste. This includes plant matter such as straw and corn stover, or leftover cornstalks and corn leaves, that contains a mix of polymers collectively called lignocellulose. This complex biopolymer is now tapped as a feedstock for the production of bioethanol. Maness has been working for over a decade to optimize the bacterium Clostridium thermocellum to generate hydrogen from corn stover.

Maness chose to focus on C. thermocellum in the early 2000s because, unlike many other bacteria, it was known to feed on cellulose—the dominant component of lignocellulose—without any need to pretreat it, Maness says. C. thermocellum breaks down cellulose to produce hydrogen and CO2 while producing lactic acid, formic acid, and ethanol as by-products. Over the years, Maness and her team gradually optimized C. thermocellum’s hydrogen production from cellulose by finding competing pathways and knocking them out using genetic engineering. In 2016, a preliminary life-cycle analysis conducted by Argonne’s Dai found that Maness’s fermentation process, combined with measures to maximize the amount of energy and hydrogen recovered, produced up to 30% less carbon dioxide per kilogram of hydrogen compared with steam reforming of natural gas.

Later that year, Maness’s team identified a pathway in C. thermocellum that actively consumes CO2 produced by the bacteria (Proc. Natl. Acad. Sci. U.S.A. 2016, DOI: 10.1073/pnas.1605482113). That means the carbon dioxide that is evolved during hydrogen production is recaptured by the bacteria to build cell mass, and less CO2 would need to be sequestered or captured.

Maness’s team has also begun genetically engineering C. thermocellum to ferment xylose, a sugar derived from hemicellulose, along with cellulose to make hydrogen (Biotechnol. Bioeng. 2018, DOI: 10.1002/bit.26590). After identifying the genes that enable xylose consumption in a different bacterium, the researchers inserted those genes into C. thermocellum. The new strain doubled hydrogen yield.

Working with wastewater

Solid waste isn’t the only type of waste that can produce hydrogen. Wastewater contains plenty of raw material that can be turned into fuel. And in 2017, more than 80% of the world’s wastewater entered the environment without any filtration or disinfection, according to an estimate by the United Nations Educational, Scientific, and Cultural Organization. The wastewater treatment that does take place consumes 2–4% of electricity produced globally.

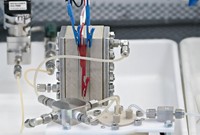

To help make a dent in the problem of raw wastewater, Princeton’s Ren is working on ways to use electroactive bacteria to produce hydrogen from wastewater while treating it. Electroactive bacteria occur naturally in sewers and wastewater treatment plants, where they consume organic matter and produce electrons that are immediately taken up by other bacteria. Researchers have learned to harvest these electrons by letting the electroactive bacteria grow on the anodes of so-called microbial fuel cells; the electrons produced flow through the fuel cells to the devices’ cathodes, generating current. In Ren’s case, he combines these electroactive bacteria with a photoelectrochemical cell to split wastewater and generate hydrogen (Environ. Sci. Technol. 2017, DOI: 10.1021/acs.est.7b03644).

In traditional water splitting, two half reactions take place: one that oxidizes H2O into O2 while generating hydrogen ions and electrons, and another that reduces those hydrogen ions into H2. The process’s efficiency tends to be limited by the first, oxygen-evolving half reaction—a thermodynamically unfavorable one that requires light or electrical power. Using wastewater sidesteps that half reaction because bacteria oxidize the organic solids in the wastewater to form CO2, a more thermodynamically favorable process that requires less energy. This provides two benefits at once: avoiding a difficult reaction while actively removing waste, says Moritz Kuehnel, a chemist at Swansea University.

Generating CO2 at the anode is unavoidable, but Ren claims that the CO2 could be sequestered or otherwise captured to further reduce the carbon footprint of this process.

In a proof-of-concept experiment, Ren and his team set up a photoelectrochemical cell with a bioactive anode coated with a naturally occurring mix of electroactive bacteria and a photoactive gallium-indium cathode. When light shines on the cathode, excited electrons reduce hydrogen ions in the wastewater to form hydrogen, leaving positively charged holes. The holes are then filled with electrons from the anode, produced by the electroactive bacteria munching on the organic waste.

The researchers are now trying to push their technologies toward commercialization. Mohan claims that the full-scale digesters he is negotiating to build could produce hydrogen cost competitively with steam reforming of natural gas.

Maness’s team is working with a 5 L reactor on a bench top, actively trying to scale up. The process’s efficiency is low, limited partly by the fact that solid lignocellulose makes the mixture viscous and difficult to stir. To overcome this problem, Maness is collaborating with scientists from Lawrence Berkeley National Laboratory to design a mixing reactor that can handle high amounts of solids.

In addition to organic waste, other fast-growing waste streams like plastics could potentially be tapped for hydrogen and valuable chemicals, and researchers like Reisner and Kuehnel are developing the chemistry for doing so. A diversity of methods for making hydrogen, Maness says, is key for it to become successful as a fuel. Although the research still has a long way to go, Ren says the prospect of “killing two birds with one stone”—producing a clean fuel while treating waste—makes it worth the effort.

XiaoZhi Lim is a freelance writer. A version of this story appeared in ACS Central Science: cenm.ag/hydrogen.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter