Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Eastman partners with Seen for bird-friendly glass

Visible elements in the glazing interlayer help birds avoid deadly collisions

by Craig Bettenhausen

November 4, 2020

| A version of this story appeared in

Volume 98, Issue 43

Billions of birds meet their end each year smacking into glass windows at full-flight speed. Among causes attributable to human activity, only predation by house cats beats glass in avian deaths in the US, according to the American Bird Conservancy.

The solution is conceptually simple: make glass that birds can see. To that end, Eastman Chemical is teaming up with Seen, a Swiss architectural-surfaces specialist, to market a line of bird-safe interlayers for laminated architectural glass. The partnership fits in with Eastman’s existing business in polyvinyl butyral (PVB) interlayers for architectural and automotive safety glass.

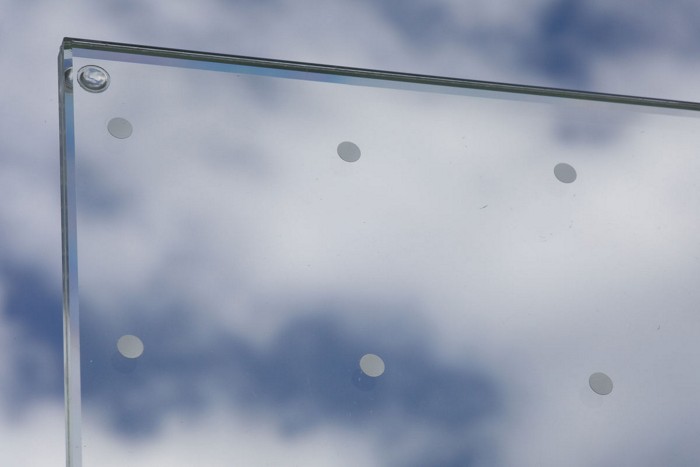

Laminated glass is typically made by sandwiching a thin PVB film between two layers of glass. Seen’s film includes 9 mm metallic discs spaced 90 mm apart. Though that’s smaller and more spaced out than what ecologists normally recommend, the bird-strike testing facility Biological Station Hohenau-Ringelsdorf said the glass “ranks among the best collision avoiding solutions tested so far,” according to Seen.

Some solutions to the bird-strike problem rely on materials that absorb or reflect wavelengths of light that birds can see but humans can’t. Eastman views having a visible product as an advantage. “Everybody can see it and will be aware there is a feature in the glass,” the firm says. Also, most competing products are screen-printed or applied as a film on the outside of the glass. Inside the interlayer, the discs will see less wear and tear.

The firms hope that having an aesthetically pleasing material with an ecological story to tell will help speed adoption.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter