Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Polymers

Strong and tough synthetic yarn

Combination of physical and chemical techniques aligns and links polymer fibers

by Bethany Halford

December 13, 2019

| A version of this story appeared in

Volume 97, Issue 48

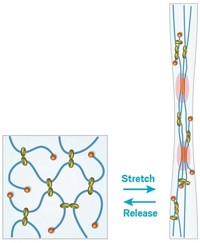

While the humble spider has no trouble spinning silk that’s both strong and tough, makers of synthetic fibers have found there’s usually a trade-off between these two properties. If a material is strong—that is, it resists deformation—usually it lacks toughness, making it prone to fracture, and vice versa. By combining chemical and physical approaches, a team led by the University of Bayreuth’s Andreas Greiner has managed to make polymer yarns that have properties on par with those of spider silk (Science 2019, DOI: 10.1126/science.aay9033). To achieve the combination of strength and toughness, the researchers electrospun poly(acrylonitrile-co-methyl acrylate) yarns with a small amount of poly(ethylene glycol) bisazide—a linking molecule. They then heat stretched the yarns and allowed them to cool under tension. This process aligns the fibers in the yarns and covalently links them to one another via a so-called click reaction (shown). “This underlying principle can be used to create similar strong and tough fibers from other commodity polymers in the future,” the researchers write, “and can be used in a variety of applications in areas such as biomedicine, satellite technology, textiles, aircrafts, and automobiles.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter