Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

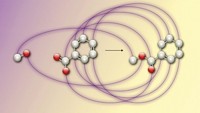

Computational Chemistry

New software could run the lab of the future

ChemOS helps chemists by letting robots perform experiments in their labs

by Sam Lemonick

March 26, 2018

| A version of this story appeared in

Volume 96, Issue 13

Robots have repeatedly demonstrated that they can do the work that humans do. And chemists haven’t escaped this automation trend. Food, pharmaceutical, and other industries have sped up routine processes by using robots to sample and analyze products. Chemists have designed programs like Chematica to let computers plan synthetic routes. Research groups have even demonstrated nearly autonomous systems that use machine learning to design, carry out, and evaluate experiments.

But the cost and complexity of some of these systems make them unattainable for many chemistry labs. At the ACS national meeting in New Orleans last week, Alán Aspuru-Guzik of Harvard University described a free software package called ChemOS that he developed to make the tools of automation available to more scientists.

“If you look at the chemistry lab of the 16th century or even the 21st century, you will see the same thing,” in terms of how chemists run experiments, Aspuru-Guzik said. “Nothing has changed really. If we really want to rethink discovery, we need to rethink the laboratory.”

ChemOS uses machine learning to interpret commands from users and then plan, execute, evaluate, and refine experiments. It can communicate with humans through email or platforms like Slack and Twitter. It can also interact with other automation software like the programs that control robotic arms or solution injectors on laboratory machines. Aspuru-Guzik compared it to a brain, performing the higher-level functions needed to coordinate a successful experiment.

Aspuru-Guzik and colleagues recently demonstrated some uses of ChemOS (ChemRxiv 2018, DOI: 10.26434/chemrxiv.5952655). In one example, the program figured out how to make a tasty cocktail. ChemOS controlled a robotic liquid pump to mix possible ingredients for a drink, including those needed to make a Tequila Sunrise—orange juice, grenadine, and tequila—as well as vinegar. ChemOS learned to improve its recipe based on group members’ ratings. Aspuru-Guzik said such human input could be important for robots making food, cosmetics, or other products that depend on human approval.

His group also demonstrated how ChemOS could run experiments in remote labs. Aspuru-Guzik designed an experiment at Harvard and used ChemOS to carry it out with equipment on the other side of the continent in the laboratory of organic chemist Jason E. Hein at the University of British Columbia. Running experiments from centralized laboratories could reduce costs and improve efficiency, Aspuru-Guzik said.

At the meeting, Aspuru-Guzik also described how ChemOS could help find new materials. He said autonomous systems could quickly screen and optimize methods for making carbon nanotubes or discover new metal-organic frameworks that could help us generate, store, and use energy in more environmentally friendly ways.

A program like ChemOS could be a boon for high-throughput screening, said S. Joshua Swamidass, a bioinformatics scientist at Washington University in St. Louis. He has created algorithms to make screening more efficient and said they could have a broader impact if integrated into software like ChemOS.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter