Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Catalysis

Chemists crack catalytic chemical recycling of polyethylene

Common plastic can be broken down to make the commodity chemical propene

by Leigh Krietsch Boerner

September 29, 2022

| A version of this story appeared in

Volume 100, Issue 35

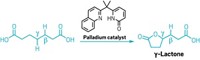

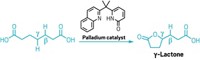

Chemists at the University of California, Berkeley, have found a way to turn polyethylene (PE) plastics into propene, which can then be used to make new materials. This method of chemical recycling is one of the few to target the commonly used PE and one of the first to completely break down the plastic into a single product. Organic chemist John Hartwig and his group used three catalysts to transform PE into alkenes and then create propene monomers (Science 2022, DOI: 10.1126/science.add1088). The reaction makes few side products, yields over 80% propene, and works under mild conditions. The team used an iridium catalyst to remove hydrogens from PE, creating alkenes, and then a ruthenium catalyst to transform these to terminal alkenes. The Palladium catalyst works together with a ruthenium catalyst in a process called isomerizing ethenolysis to produce propene and another alkene with one less carbon in its chain. That alkene reenters the ethenolysis cycle to produce another propene. “So if you have polyethylene that we cut into chains of 100 carbons, it does that [cycle] 100 times to get down to the end of the chain,” Hartwig says. PE is particularly tricky to take apart, he says, because it’s composed of unstrained carbon-carbon single bonds, which require extreme temperatures to break. This new method proceeds at 200 °C. Though not yet ready for commercial use, the method shows that chemists can transform hard-to-react waste PE into something useful via common organic reactions.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter