Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Fluorination

Fluorine chemistry, hold the HF

Grinding fluorite and phosphate together creates a stable solid fluorination reagent

by Brianna Barbu

July 23, 2023

| A version of this story appeared in

Volume 101, Issue 24

A new paper in Science could shake up the way fluorochemicals are made. Researchers from the University of Oxford, led by Véronique Gouverneur, have found that it is possible to produce a stable, solid fluorinating reagent directly from CaF2 with no toxic hydrogen fluoride (HF) involved (Science 2023, DOI: 10.1126/science.adi1557).

Molecules containing fluorine have proven useful in a multitude of products, including drugs, pesticides, refrigerants, batteries, and polymers. It’s estimated that 20% of drugs and 30% of agrochemicals on the market bear at least one fluorine atom, though the element is also used in environmentally concerning materials such as per- and polyfluoroalkyl substances.

Every fluorine atom in human-made molecules ultimately comes from the same mineral source: CaF2, also known as fluorspar or fluorite. But getting those fluorines into a form where they are usable for synthesis has, for the past 250 years, involved reacting CaF2 with sulfuric acid to make HF gas. It’s an energy-intensive process, and HF is extremely toxic and difficult to handle, but a viable alternative has proven elusive.

Gouverneur thought it was high time there were safer and more sustainable alternatives for accessing fluorine chemistry. “We wanted to be a bit bold about this, and try to see whether we can really make a drastic difference” in how fluorochemicals are produced, she says.

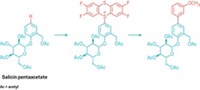

Inspired by biomineralization, the researchers wanted to see if they could displace the fluoride from CaF2 using phosphate ions. The lattice energy of calcium phosphate is higher than that for CaF2, providing a thermodynamic push for swapping ions around. And indeed, when the researchers ground CaF2 together with potassium phosphate in a ball mill, they obtained a solid substance that works as a nucleophilic fluorine source.

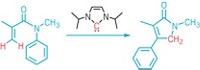

The reagent, which the researchers dubbed Fluoromix, successfully installs fluorine atoms onto organic molecules via halogen exchange. The researchers used it to make a variety of molecules with S–F and C–F bonds, including deoxyfluorination reagents such as PyFluor, fluorinated bioactive molecules, and aryl fluoride building-block compounds.

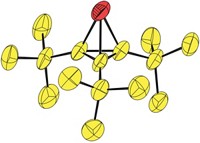

Michael Hayward, an inorganic chemist at the University of Oxford, was instrumental in illuminating what Fluoromix is made of and how it forms. Powder X-ray diffraction revealed that it’s actually a mixture of two different inorganic salts, K3(HPO4)F and K2−xCay(PO3F)a(PO4)b. Both possess the ability to facilitate fluorination.

“That was almost a year of work, just to sort of figure out on an atomic level what was happening,” says Calum Patel, a graduate student in Gouverneur’s lab who worked on the project.

Tobias Ritter, an organic chemist who researches fluorination reactions at the Max Planck Institute for Kohlenforschung, says “it’s one of those papers that’s as simple as it is ingenious.” It’s impossible to predict precisely what effect this work will have on the fluorochemical industry, he says. But he believes it “definitely has the potential to really make a dent” in the problem of how to do fluorination more sustainably, because it cuts to the very beginning of the supply chain.

Gouverneur and Gabriele Pupo, who worked on the project as a postdoc, cofounded a start-up, Fluorok, in 2022 devoted to HF-free fluorination chemistry.

The immediate next steps for Gouverneur and Patel are to continue exploring Fluoromix’s reactivity. They hope many others in the chemistry community will join them. But more importantly, they hope that this work will inspire other scientists to tackle big challenges and reimagine other chemical processes to be more sustainable.

“It’s not until you look into the risky science that you really start shining light into new fields,” says Patel.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter