Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

3-D Printing

Printable polymer with tunable structural color

Light-controlled cross-linking can change material’s optical properties on the fly

by Brianna Barbu

February 26, 2024

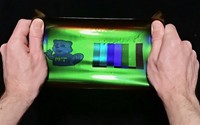

Ying Diao, a chemical engineer at the University of Illinois Urbana-Champaign (UIUC), has always been fascinated by structural color, which comes from light waves interacting with a material on the nanoscale. Structural color, found naturally in some bird feathers, insect shells, and plants, is as a manufactured colorant, more vibrant and potentially more eco-friendly than pigment-based color. It can be created in the lab in a few ways; Diao’s approach uses a 3D-printable block copolymer whose chains can self-assemble into photonic nanostructures that bend light just so.

Now Diao and her collaborators at UIUC have devised a way to change the polymer’s perceived color during the printing process, using light to control cross-linking within the polymer (Proc. Natl. Acad. Sci. U.S.A. 2024, DOI: 10.1073/pnas.2313617121). “We want to push the frontier of 3D printing towards controlling nanoscale structures,” Diao says.

Diao says that the ability to control a material’s color with light was a serendipitous discovery. Graduate student Sanghyun Jeon, who was experimenting with cross-linking photonic copolymers using a light-controlled reaction to make 3D structures, discovered that the color of the final material depended on the light intensity during cross-linking and decided to figure out why.

The researchers learned that the cross-linking reaction and the chain self-assembly happen at similar rates, so changing the amount of cross-linking between the polymer chains changes how they arrange themselves on a nanoscopic level. More intense light exposure leads to denser cross-linking, which means smaller nanoscale layers and a bluer color. With this understanding and a little fine-tuning, the researchers were able to upgrade their setup to control the color of the material as it cures.

Garret M. Miyake, a polymer chemist at Colorado State University and a cofounder of Cypris Materials, a start-up working to commercialize structural color coatings made from self-assembling block copolymers, calls the UIUC team’s work “a very creative approach” to producing multiple colors from a single polymer.

The researchers are continuing to study, using machine learning, how to precisely control color and other material properties through changes to the polymer structure and processing conditions. “While we got lucky in this case, what we’d like to do is make our own luck,” says Charles Sing, a polymer physicist at UIUC who worked on modeling the assembly mechanism.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter