Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Green Chemistry

Liquid Light

Adapting electrochemistry to make greener chemicals

by Marc S. Reisch

November 2, 2015

| A version of this story appeared in

Volume 93, Issue 43

Making chemicals in an electrochemical cell is not new. What is new is Liquid Light’s process for converting carbon dioxide, water, and solar energy into a precursor for plastic water bottles.

Liquid Light

Launched: 2009

Location: Monmouth Junction, N.J.

Focus: Making CO2 a practical feedstock for multicarbon chemicals

Technology: Low-energy catalytic electrochemistry

Founders: Andrew Bocarsly, Emily Cole, Fouad ElNaggar, and Kyle Teamey

Funding: More than $15 million from investors including BP Ventures, VantagePoint Capital Partners, and Osage University Partners

Electrochemistry has been practiced for decades to make chlorine and caustic soda from salt-laden water. Like the chlor-alkali process, Liquid Light’s system is an aqueous-based system, points out Emily Cole, chief science officer and a Liquid Light founder.

But in a twist on the old technology, Cole and her colleagues at the Princeton University spin-off are taking a gas implicated in climate change—CO2—and a clean energy source to make environmentally friendlier replacements for industrial chemicals. For its first commercial product, the firm is seeking to make ethylene glycol, one of two monomers used to create polyethylene terephthalate (PET) for water and soda bottles. The other monomer is terephthalic acid.

Backing Liquid Light in its quest are petrochemical maker BP and venture capital firms, such as VantagePoint Capital Partners and Osage University Partners, that have provided more than $15 million in funding since the firm’s founding in 2009.

Another important supporter is Coca-Cola, which signed a technology development agreement with the start-up in July. That made Liquid Light one of a select group of biobased chemical intermediate firms in the beverage maker’s “green” PET bottle development program, called PlantBottle.

The first source of CO2 that Liquid Light wants to use is a corn ethanol facility, explains chief executive officer Dave Law, a former Covestro chlor-alkali operations executive. “But we’re agnostic as to the source of the CO2,” he says.

For ethylene glycol, the Liquid Light process works by combining CO2 with water, which enables hydrogenation in an electrochemical cell. Inside the low-energy cell, a proprietary catalyst-coated electrode produces a formate salt that is converted to oxalic acid. In a separate process step, the oxalic acid is further hydrogenated into ethylene glycol.

By using different catalysts and other feedstocks in place of water in the electrochemical cell, the firm can also make coproducts such as chlorine and acrylic acid. “The catalysts are our secret sauce,” Law says.

Ethylene glycol for the PlantBottle today comes from sugar-based ethanol that is dehydrated to ethylene, converted to ethylene oxide, and then to ethylene glycol. “We believe our process reduces the number of steps to make ethylene glycol, is more economical, and reduces CO2 emissions to the atmosphere,” Law says.

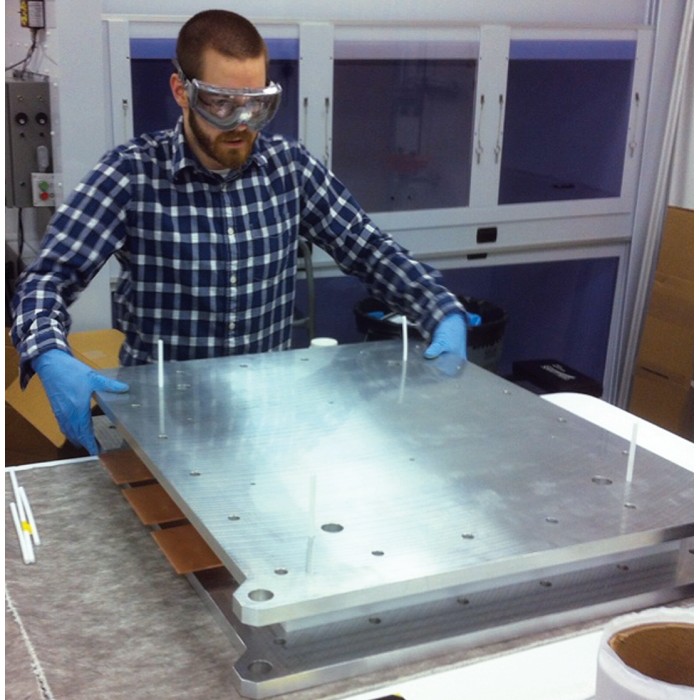

So far, Liquid Light has secured 25 patents based on work done at a bench-scale facility in Monmouth Junction, N.J. The lab is not far from Princeton, where Cole and chemistry professor Andrew Bocarsly did the initial research on the firm’s technology.

Liquid Light expects to have a pilot-scale plant running by 2017 in Alberta. Support for that effort is coming partially from the Climate Change & Emissions Management Corp., an Alberta-funded nonprofit that also has provided Liquid Light with a $500,000 research grant. Ultimately, the firm hopes to make money by licensing its technology to chemical makers, Law says.

Find out what Liquid Light has been up to since it appeared on C&EN’s 2015 Top Start-ups List by clicking here.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter